- Home

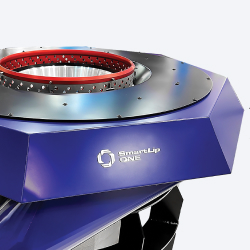

- SolutionsAutomatic Air Ring

Control film thickness and achieve constant film gauge automatically.

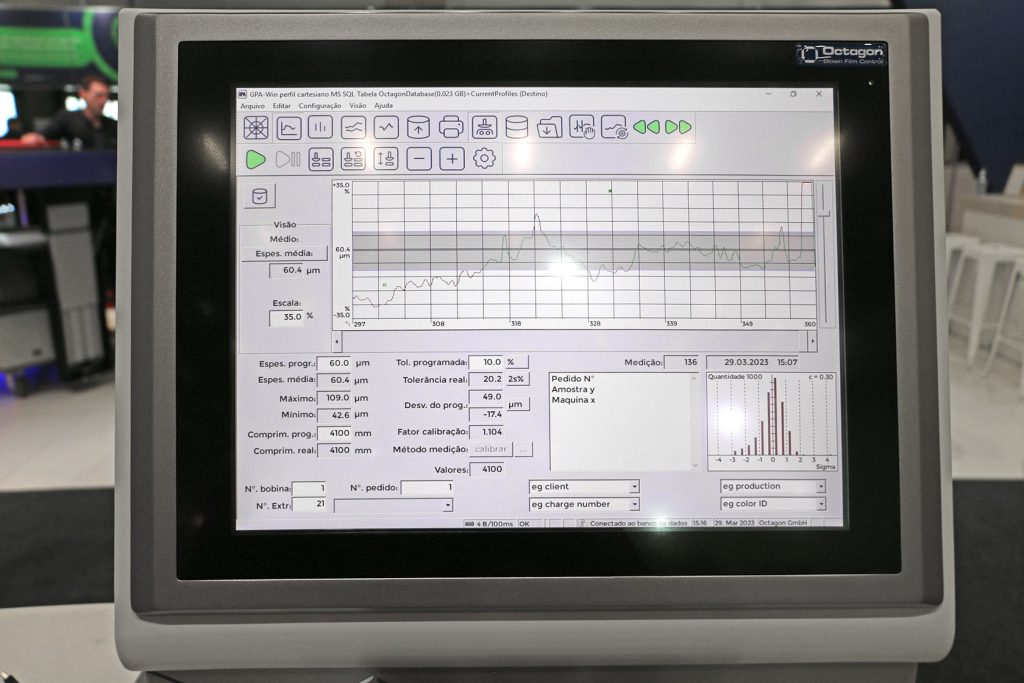

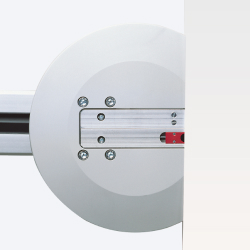

Film Thickness MeasurementInline and real-time gauging data to automate film production adjustments.

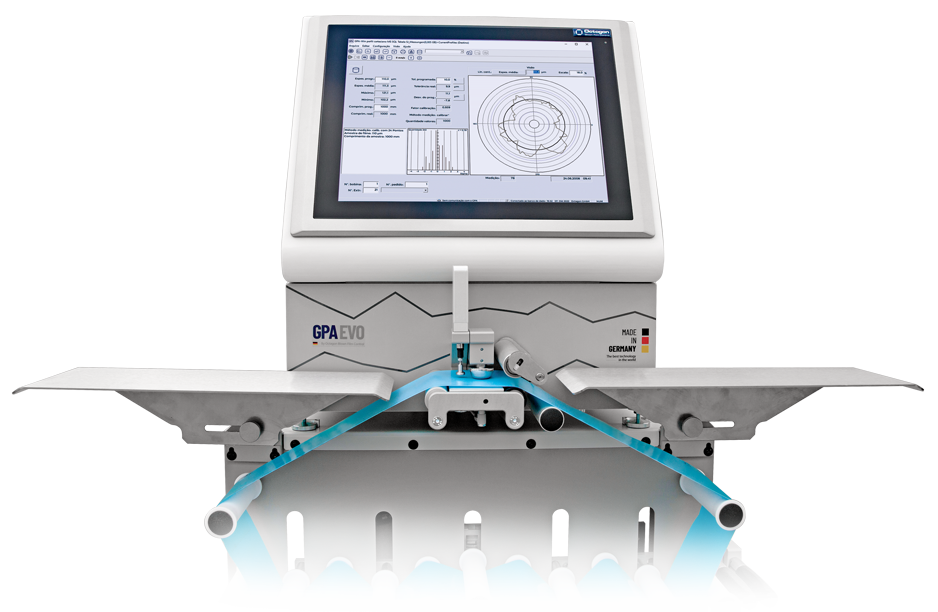

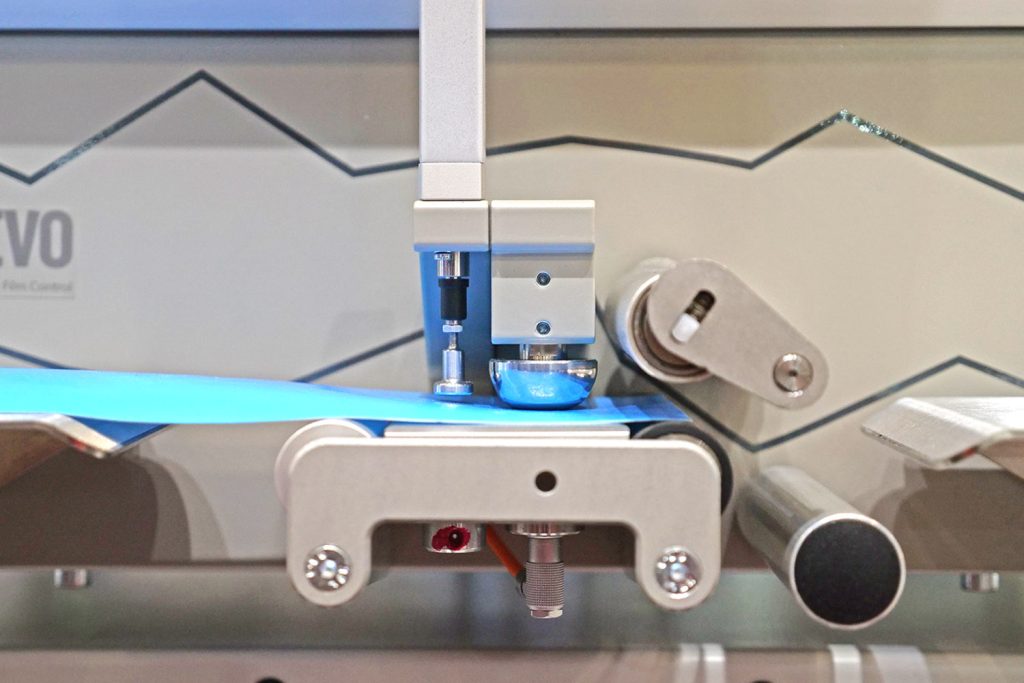

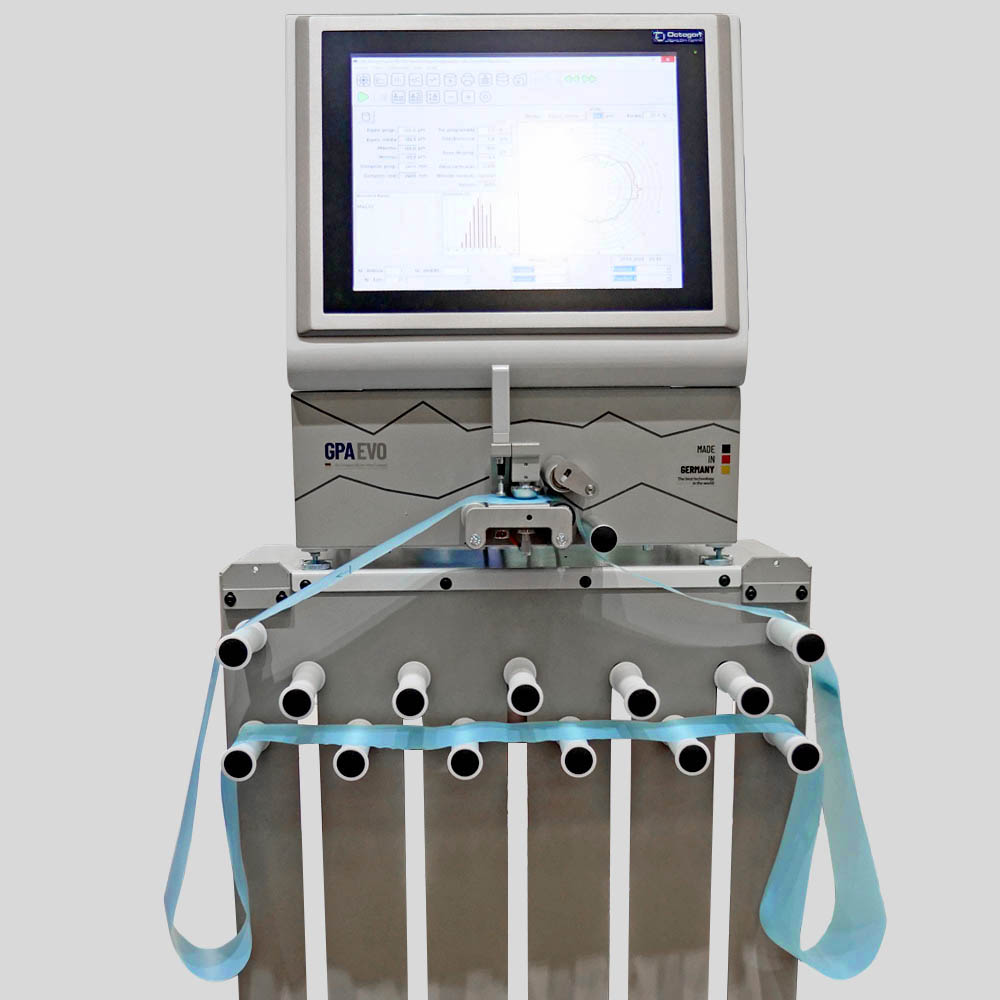

Offline Film GaugingMeasure plastic film thickness in lab and guarantee quality expectations

Film Width ControlMeasure and automatically control the width of your plastic film extrusion line.

Gravimetric Dosing & FeedingUltra accurate plastic material feeding and dosing with gravimetric technology.

Film Production ManagementSystems and software to automate quality control for plastic film extruders.

Film Extruder UpgradeCustom projects and retrofitting of legacy and outdated extrusion lines.

LAUNCH: SmartLip One

Meet our most advanced automatic air ring with a single air inlet.

Read More - About Us

- Support

- News