After an intense and inspiring week at K 2025 in Düsseldorf, Germany, the Octagon team reflects on what was undoubtedly one of the most significant milestones in our 38-year history. From October 8 to 15, we had the privilege of welcoming industry leaders, innovators, and partners from over 60 countries to our stand in Hall 10 / B09, where we unveiled technologies that are reshaping the future of blown film extrusion.

The Revolution We Promised

When we announced our presence at K 2025 with the tagline “A New Era of Extrusion,” it wasn’t just marketing rhetoric—it was a promise. A promise that we kept by introducing Integrated Artificial Intelligence directly embedded into our blown film control systems, marking the industry’s first true leap into intelligent automation.

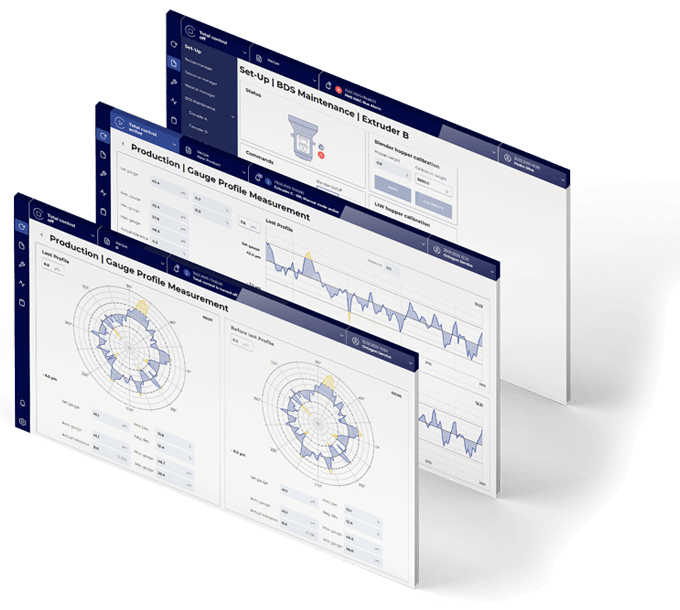

Unlike traditional automation that simply follows pre-programmed instructions, our AI-powered systems think, learn, and adapt in real-time. This isn’t about replacing human expertise—it’s about amplifying it with technology that anticipates problems before they occur, optimizes production continuously, and delivers results that were previously impossible to achieve consistently.

What Makes This AI Different?

The artificial intelligence we showcased at K 2025 operates on four fundamental principles:

Prediction: Advanced neural networks analyze current production conditions and predict future system behavior with remarkable accuracy. This allows the system to make proactive adjustments rather than reactive corrections.

Optimization: Within milliseconds, our AI calculates optimal adjustments across multiple variables—air flow, temperature, pressure, and more—to maintain perfect film characteristics under any conditions.

Execution: Corrections are applied in real-time through seamless integration with all Octagon control systems, ensuring immediate response to production variations without human intervention.

Learning: Every production cycle generates data that enhances the AI’s capabilities. The system literally becomes smarter and more efficient over time, creating a self-improving production environment.

The results speak for themselves: customers implementing our AI-powered solutions are experiencing up to 35% increases in production throughput and 70% reductions in thickness profile tolerances—metrics that translate directly into competitive advantage and profitability.

SmartLip ONE: Redefining Air Ring Technology

Among our product launches at K 2025, the SmartLip ONE automatic air ring garnered exceptional attention from visitors and industry experts alike. This revolutionary system features a game-changing single air inlet design that eliminates the complexity of traditional multi-inlet systems while delivering superior performance.

Engineering Excellence in Every Detail

The SmartLip ONE’s exclusive internal design achieves perfect air flow distribution through a single inlet, significantly reducing internal pressure and energy consumption. But the innovation doesn’t stop there:

- Advanced Insulation System: Our proprietary thermal insulation is 85% more efficient than competing solutions, drastically reducing water condensation—a common problem that affects film quality and causes unscheduled downtime.

- Dual and Triple Lip Configurations: Available in two models, with the Triple Lip specifically designed for maximum output applications, featuring our robust elevation system with reinforced structure and digital positioning.

- Contractual Performance Guarantees: We’re the only company in the sector confident enough to guarantee production gains by contract, demonstrating our absolute confidence in SmartLip technology.

Field-proven results demonstrate that SmartLip DL (Dual Lip) configurations deliver production gains of 23% compared to 16% from competitors, while SmartLip TL (Triple Lip) achieves 34% gains versus 25% from alternative solutions.

Complete Integration: The Octagon Advantage

What truly sets Octagon apart in the industry became crystal clear during K 2025: our ability to deliver fully integrated solutions that work in perfect harmony. Every component—from raw material feeding to final quality control—is designed, developed, and manufactured by the same engineering team.

The Complete Production Chain

Smart Feeding Systems: Our 100% stainless steel intelligent vacuum technology ensures continuous, optimized material flow with fully automated operation.

SmartGDS & SmartBDS Gravimetric Dosing: Precision dosing systems that guarantee accuracy up to ±0.5% of nominal value (SmartGDS) and 0.01% of batch volume (SmartBDS), with ROI typically achieved within months through raw material savings.

Smart IBC (Internal Bubble Cooling): High-precision dynamic control with Siemens S7 PLC ensures perfect cooling and bubble geometry management, with contractual guarantees on efficiency improvements.

Calibration Basket: Sophisticated bubble stabilization with diameter ranges from 140 to 1943 mm, featuring automatic opening/closing synchronized with width control systems.

Advanced Sensors: Our PMS-B, PMS-FF, and VenPad thickness measurement sensors deliver 0.1 µm resolution, while LMS and GMS width control systems provide ±1 mm accuracy.

ScenEx Pro Software: The intelligent brain that unifies all systems, providing real-time analytics, comprehensive reporting, and Industry 4.0 ready integration accessible via any device.

GPA Evo: Laboratory-grade offline measurement equipment ensuring ISO and DIN compliance with millimetric precision.

This unified architecture eliminates compatibility issues and ensures seamless communication between all systems. When hardware and software are designed together by the same team, the result is unmatched reliability and superior performance that only true integration can deliver.

Global Connections, Local Expertise

One of the most rewarding aspects of K 2025 was the diversity of conversations we had with industry professionals from around the world. From Brazil to Germany, from the United States to Southeast Asia, we were reminded that while blown film extrusion challenges may be universal, solutions must be tailored to specific needs and contexts.

Our international team of engineers—trained at our German headquarters but stationed around the world—exemplifies our commitment to “German Technical Competence with Global Presence.” This model allows us to provide local technical support with international excellence standards, ensuring our customers receive world-class service regardless of location.

The People Behind the Innovation

Technology is only as good as the people who design, implement, and support it. Throughout K 2025, our team of engineers, process specialists, and technical experts demonstrated not just technical knowledge, but genuine commitment to understanding each customer’s unique challenges and delivering solutions that work.

Every installation, every training session, every technical challenge—our team brings decades of combined experience to ensure customer success. This human element, combined with cutting-edge technology, is what transforms Octagon from a supplier into a true partner.

Looking Forward: The Journey Continues

As K 2025 comes to a close, we’re not looking back—we’re looking forward with excitement and purpose. The connections we made, the feedback we received, and the partnerships we initiated will fuel our innovation for years to come.

The new era of blown film extrusion we announced isn’t a destination—it’s a journey. And we’re honored that so many industry leaders have chosen to take that journey with us.

What’s Next?

The technologies we unveiled at K 2025 are available now. Our AI-powered systems, SmartLip ONE air rings, and complete integrated solutions are ready to transform your production line today.

For customers who visited us at the fair, our team will be following up on conversations and project discussions in the coming weeks. For those who couldn’t attend K 2025, we invite you to contact us to learn how Octagon’s innovations can address your specific production challenges.

Thank You

From everyone at Octagon, thank you to all who visited our stand, engaged with our technology, and shared in our vision for the future of blown film extrusion. Your questions challenged us, your insights inspired us, and your trust in our innovation means everything.

The future of blown film extrusion is intelligent, integrated, and inclusive. And that future is now.