Industry 4.0, also known as the fourth industrial revolution, is a term used to describe the incorporation of advanced technologies, such as artificial intelligence, the internet of things, and robotics, into industrial production. It is based on four fundamental pillars: connectivity, automation, data analysis, and customization.

These technologies have the potential to significantly transform the plastics sector, helping to improve efficiency, reduce costs, and increase innovation.

One of its main advantages in the plastics sector is the automation of production processes. The incorporation of robots and other advanced technologies allows for the automation of repetitive and dangerous tasks, increasing efficiency and reducing operational costs. In addition, the internet of things and automation allow for real-time monitoring of production processes, which can help identify problems and improve the quality of the final product.

Another advantage in the plastics sector is the ability to customize production. The incorporation of advanced technologies, such as artificial intelligence and 3D printing, allows for the production of customized pieces in small quantities, increasing flexibility and innovation.

In addition, it can also help improve energy efficiency in the plastics sector. With the incorporation of monitoring and control technologies, companies can reduce energy consumption and, in turn, decrease their operational costs.

It also has the potential to contribute to the preservation of the environment. The incorporation of advanced technologies, such as recycling and reusing plastic waste, can help reduce the environmental impact of the sector. In addition, it can also help improve safety in the workplace, reducing the risks of accidents and work-related illnesses.

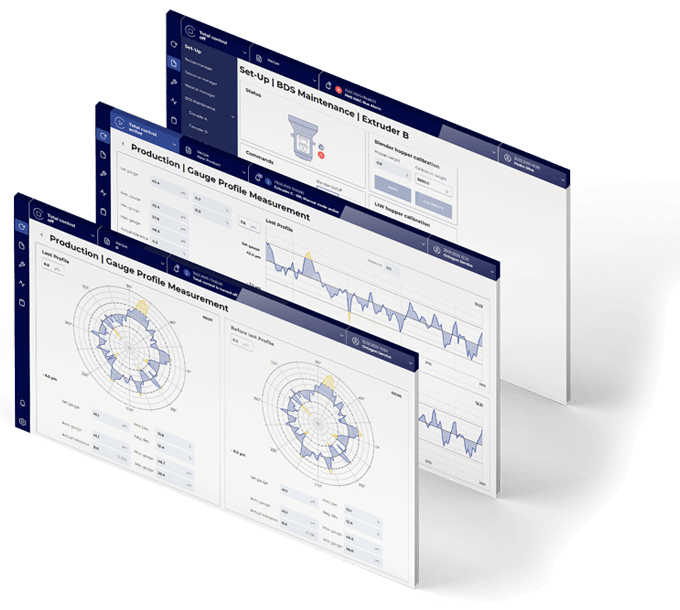

We at Octagon are developing our products based on the benefits that the “fourth industrial revolution” provides in all processes. Our great example of innovation is in our big launch, the SmartGDS. This product is one of a kind in the market and in addition to being fully prepared for Industry 4.0, it has a web-based HMI that is fully oriented to be intuitive for the operator.

This industrial revolution has the potential to bring many benefits to the plastics sector, including automation of production processes, customization of production, improvement of energy efficiency, and increased innovation and flexibility. The incorporation of these advanced technologies can be a great opportunity for companies in the plastics sector to adapt and remain competitive in the global scenario.”