March 24-28, 2025 | São Paulo Expo

Octagon was present at the fourth edition of Plástico Brasil 2025, Latin America’s largest solutions trade fair for the plastics industry, held from March 24-28 at São Paulo Expo. The event, which brought together over 1,000 exhibiting brands and approximately 57,000 visitors, established itself as the leading stage for innovation, technology, and sustainability in the sector.

Technologies Presented

Throughout the five-day trade fair, we presented our latest technological solutions for blown film extrusion lines to the Brazilian and international markets, reaffirming our commitment to excellence and continuous innovation.

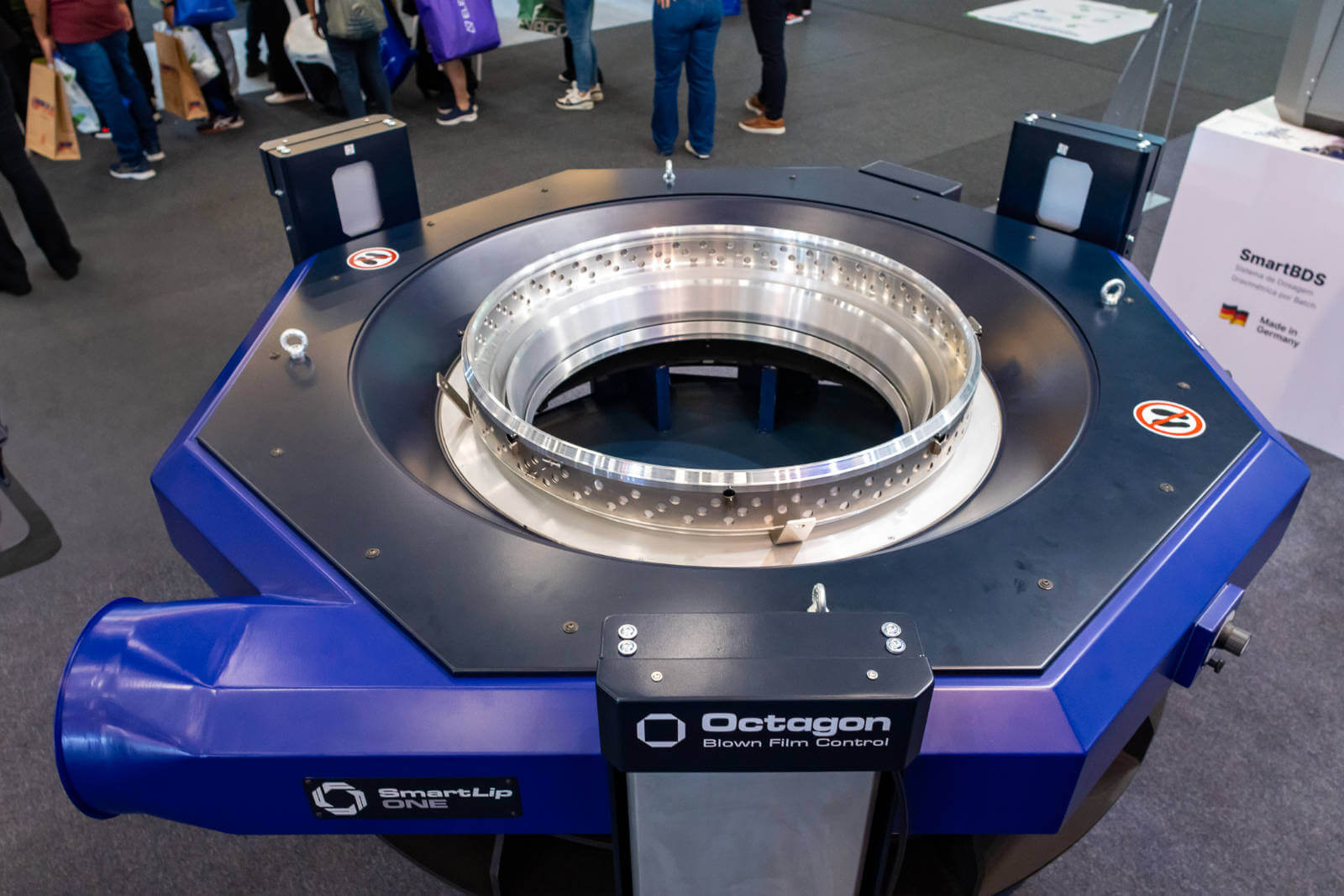

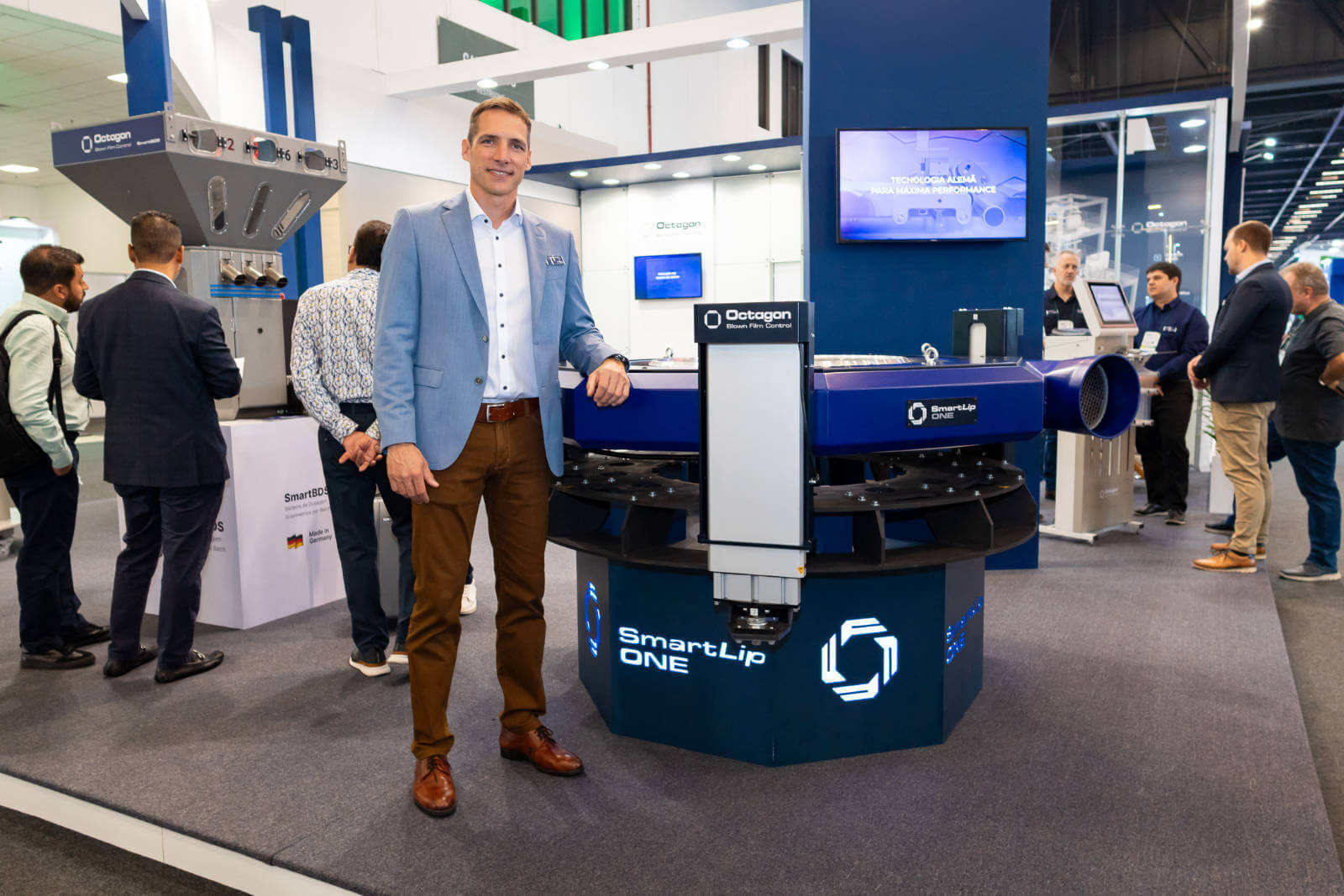

SmartLip One: Next-Generation Automatic Air Ring

The absolute highlight of our participation was the SmartLip One, our most advanced automatic air ring, equipped with an integrated lift system. Representing the pinnacle of over 35 years of development in technology for the blown film industry, the SmartLip One offers:

- Single air inlet system for maximum efficiency

- Precise film thickness control through air-modulated gauge control

- Integrated mc8 lift system for automatic adjustment of bubble geometry

- Capacity to increase productivity by up to 30%

- Reduction in thickness tolerance by up to 70%

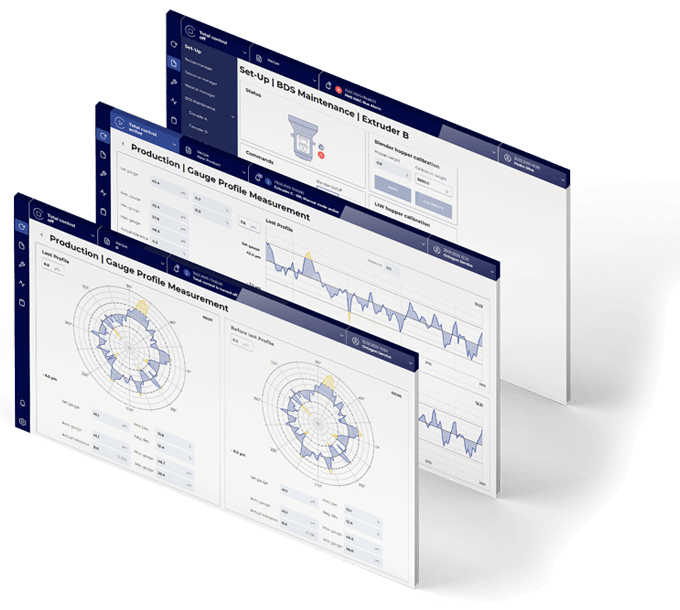

ScenEx Pro: New Automation Platform

We officially introduced to the Brazilian market ScenEx Pro, our new software platform that represents a technological leap in automation and management of extrusion lines. Integrated with all our equipment, ScenEx Pro offers:

- Optimized interface with industrial PC and touch screen for maximum ease of operation

- Real-time visualization of all production process data

- Automated control from gravimetric dosing to thickness profile

- Industrial communication via Ethernet network for continuous and secure data transmission

- SQL database for complete storage of production histories

- Intuitive dashboard with alarms, graphs, and performance indicators

Industry 4.0: Connectivity and Data Management

Our participation highlighted Octagon’s commitment to Industry 4.0 concepts, offering fully integrated solutions that transform data into strategic decisions. The integration between robust hardware and exclusive software enables:

- Real-time monitoring of production lines

- Automatic generation of comprehensive production reports

- Data analysis for preventive maintenance

- Complete traceability of the production process

- Decision-making based on data insights

Complementary Solutions

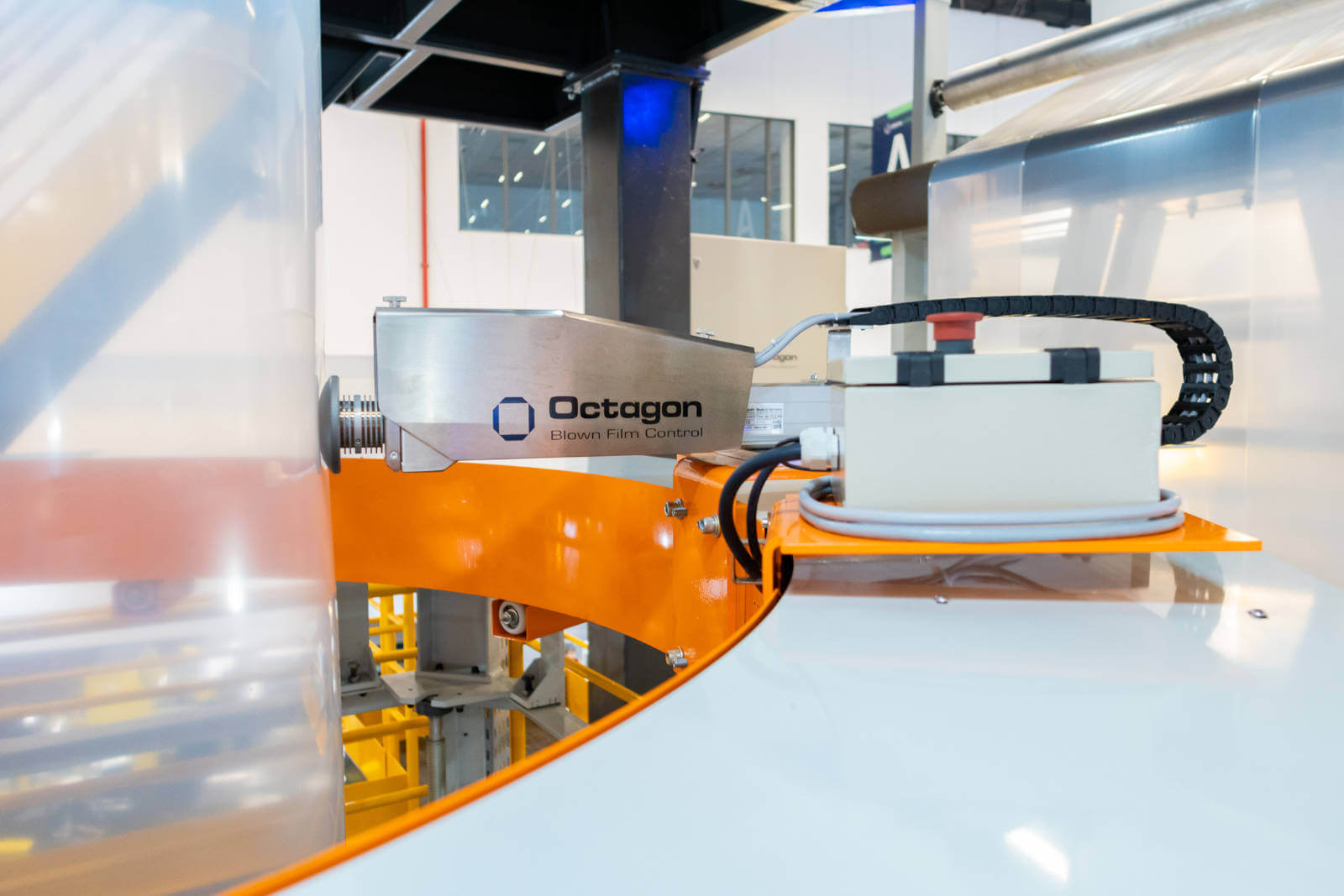

IBC and Wax Control

We presented our advanced internal bubble cooling (IBC) and wax control systems, essential for producing high-quality films with superior mechanical properties.

Gravimetric Dosing Units: Smart GDS and BDS

We showcased our complete line of high-precision gravimetric dosing units:

- Smart GDS: Intelligent gravimetric system with loss-in-weight technology for ultra-precise material dosing

- BDS: Batch doser with integrated control to ScenEx Pro

- Integrated WLS module for precise measurement of each material’s consumption through patented flow measurement system

- Automatic screw speed control to maintain film average thickness

GPA Evo with Touch Screen

The GPA Evo, our offline thickness measurement system for laboratory quality control, was presented in its most modern version, equipped with a touch screen and embedded computer. The equipment enables:

- Film thickness profile measurement with 1 measurement per millimeter resolution

- Intuitive and responsive interface with only two physical buttons

- GPA-Win software developed by Octagon

- Automatic measurement process after sample insertion

- Ideal for precise calibration of the entire extrusion line

Live Demonstration

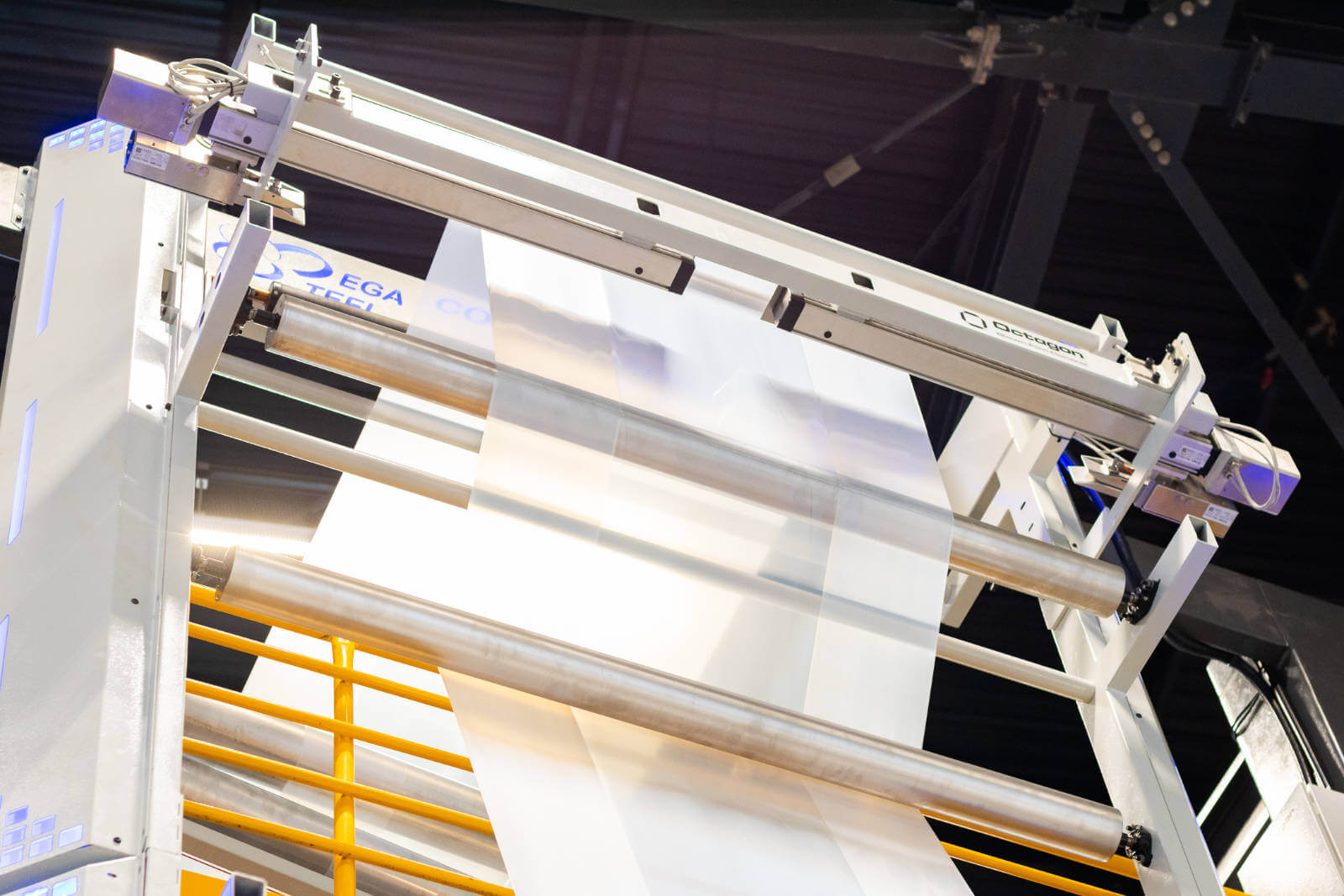

One of the major differentials of our participation was the live production line demonstration. Our equipment, SmartLip, sensors, and ScenEx Pro software, were operating in real-time on Mega Steel’s blown film extrusion line, whose booth was positioned in front of ours.

This live demonstration allowed visitors to witness the efficiency, precision, and reliability of our solutions under real production conditions, proving in practice the productivity and quality gains that our systems provide.

Networking and Business Opportunities

Plástico Brasil 2025 established itself as a strategic moment to establish new contacts, strengthen partnerships, and identify business opportunities throughout Latin America. Our technical and sales team was available to visitors throughout the event, providing:

- Customized technical demonstrations

- Consultations on process optimization

- Presentations on success cases

- Discussions about customized projects

- Specialized service in 7 languages

Over 38 Years of Technology Leadership

Octagon takes pride in its trajectory as a world leader in measurement and control technology for blown film extrusion lines. Founded in 1987, the company has established itself as a reference in innovation and quality. Our presence at Plástico Brasil 2025 reinforced this positioning, demonstrating that we continue at the forefront of technological innovation.

Our systems are present in over 61 countries, with a proven track record of machines operating 24/7 for over 30 years, ensuring:

- Unmatched operational stability

- Excellence in technical support (available onsite and remotely)

- Spare parts availability

- Continuous technological updates

- Complete training for operators and maintenance teams

Commitment to Sustainability

In line with the central themes of Plástico Brasil 2025, Octagon reaffirmed its commitment to sustainability and the circular economy. Our solutions directly contribute to:

- Material waste reduction: Precise control minimizes rejects and reprocessing

- Energy optimization: Automated processes reduce energy consumption

- Greater production efficiency: Fewer stops and faster setup

- Consistent quality: Lower variation results in fewer returns and complaints

Acknowledgment

We thank all visitors who attended our booth and learned about our solutions. It was a unique opportunity to exchange experiences, share knowledge, and demonstrate how Octagon technology can transform plastic film extrusion operations.

For companies wishing to learn more about our solutions or schedule a customized demonstration, our team remains available.

About Plástico Brasil 2025

Plástico Brasil is an initiative of ABIMAQ (Brazilian Association of Machinery and Equipment Industry) and ABIPLAST (Brazilian Plastics Industry Association), with promotion by Informa Markets. The trade fair brought together the entire plastics production chain, from raw materials, machinery and equipment, to automation solutions, recycling, and circular economy.