Octagon Innovation for Form-Fill-Seal Applications

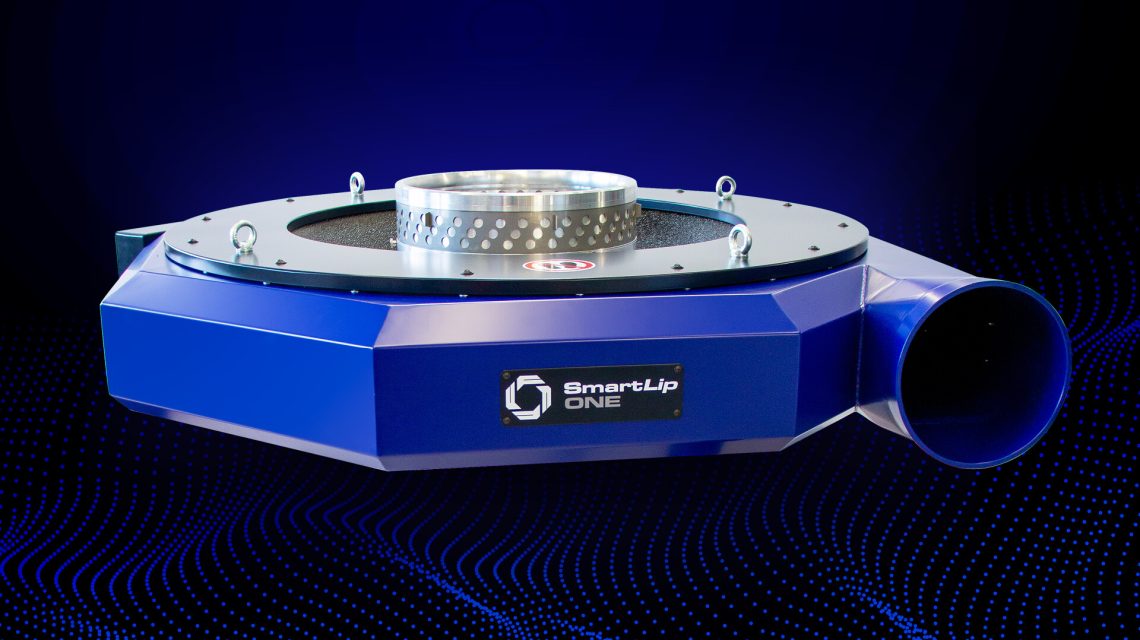

Octagon is pleased to introduce the SmartLip ONE TL FFS (2026 model), a state-of-the-art air ring specifically engineered to meet the demands of the most challenging form-fill-seal (FFS) applications in the industry.

What Makes FFS Film Special?

Form-Fill-Seal (FFS) film represents a specific and fundamental category in the automated packaging segment. Unlike conventional films, FFS film is characterized by its superior thickness and exceptional durability, essential elements for processes where mechanical strength and long-term stability are critical.

The heavier resin layers present in FFS film provide superior mechanical properties, including:

- Excellent tear resistance: Crucial to prevent ruptures during handling and transport

- High puncture resistance: Essential to protect products from external damage

- Dimensional stability: Ensuring package integrity over time

These characteristics make FFS film the ideal choice for demanding industrial applications, where packaging failure can result in significant product losses and high operating costs.

Main Applications of FFS Film

1. Granulate Packaging

FFS film is widely used in granulate product packaging, offering:

- Durability for stacking in warehouses and distribution centers

- Resistance during transport and logistics

- Protection for long-term storage

- Product integrity maintenance throughout the entire supply chain

2. Packaging of Powdered Products

For powdered products such as cement, industrial additives, and food-grade powders, FFS film provides:

- Precise filling: Dimensional control allowing exact dosing

- Reliable sealing: Prevention of external contamination

- Moisture barrier: Essential protection for hygroscopic products

- Storage integrity: Maintenance of product characteristics

3. Packaging of Fertilizers & Chemicals

In the fertilizer and chemical segment, FFS film offers:

- Superior mechanical strength: Supporting the weight and abrasive characteristics of these products

- Chemical resistance: Protection against reactions with packaged products

- Safe handling: Risk reduction during transport and storage

- Regulatory compliance: Meeting safety and environmental standards

Why SmartLip ONE TL FFS Stands Out

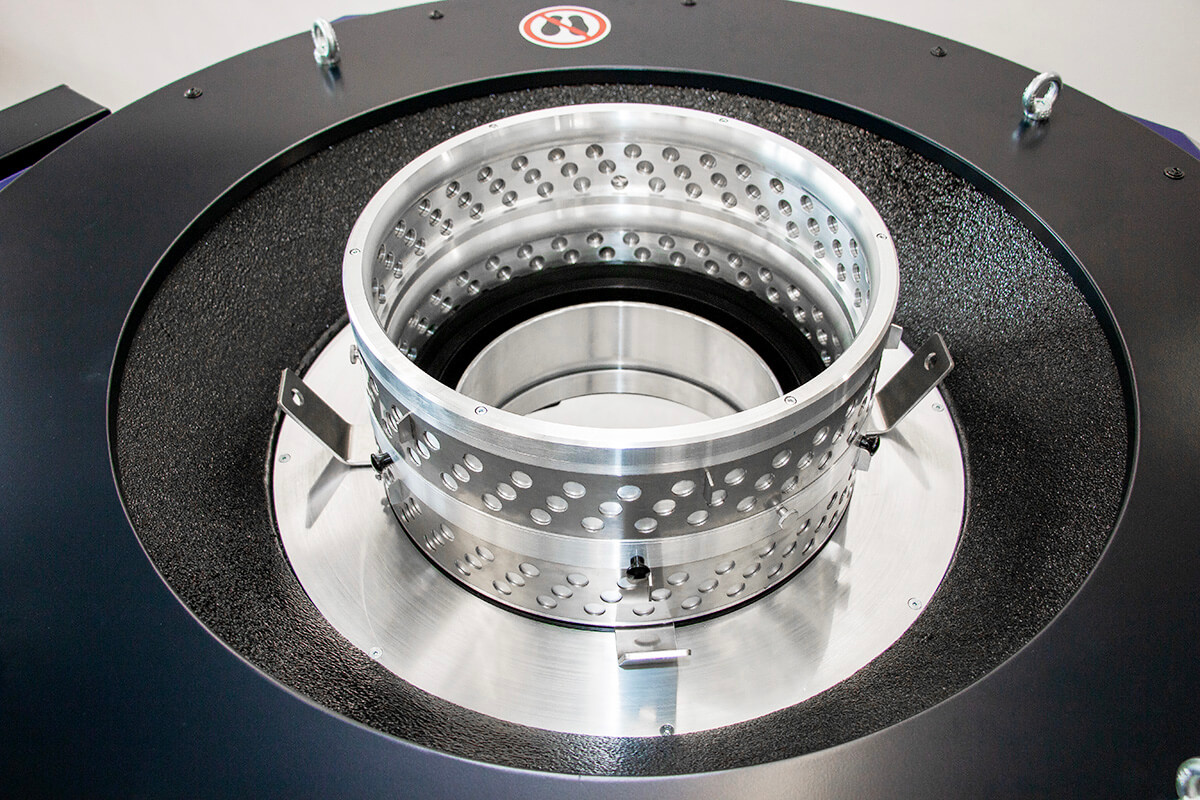

Innovative Triple Lip Design

The SmartLip ONE TL FFS incorporates an exclusive triple lip design with a specific lip set developed for FFS film particularities. This configuration allows:

- Uniform distribution of cooling air flow

- Better control of bubble formation

- Superior stability during production

Record Production

One of the most impressive highlights of the SmartLip ONE TL FFS is its production capacity:

- Throughputs of up to 600 kg/h with a die size of 180 mm

- Up to 45% production increase compared to conventional systems

- Greater operational efficiency and return on investment

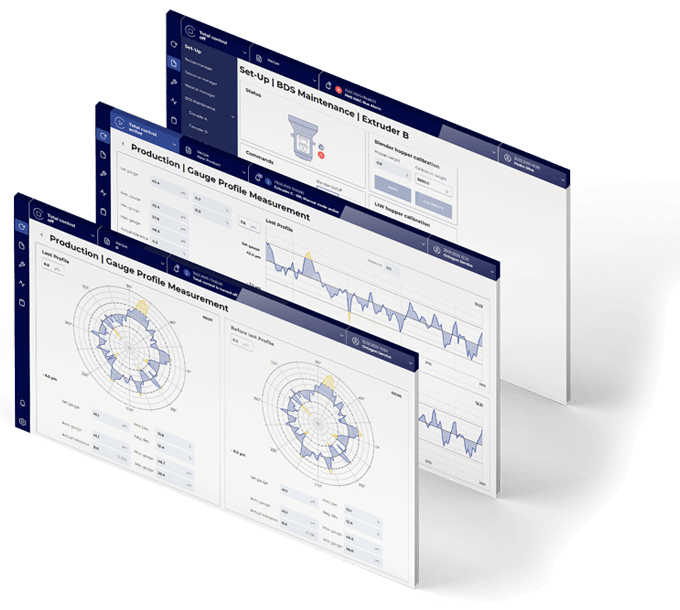

Superior Quality Control

The quality of the film produced shows significant improvements:

- Up to 70% reduction of thickness profile tolerances

- Superior film uniformity

- Lower scrap rate

- Greater consistency in final product quality

Operational Ease

The SmartLip ONE TL FFS was designed with the operator experience in mind:

- Adjustment of upward and downward air flows via two wheels: Intuitive and precise control

- Elevation device: Facilitates equipment cleaning and maintenance

- Single air inlet: Simplifies installation and reduces infrastructure costs

Advanced Technology

Technical features ensuring superior performance:

- Advanced insulation: Minimizes water condensation, avoiding quality issues

- Robust design: Built to operate continuously in demanding industrial environments

- Compatibility: Easy integration with existing extrusion lines

The Octagon Philosophy: Custom Solutions

At Octagon, we understand that each customer has unique challenges in their production processes. Our approach goes beyond providing equipment: we develop custom solutions that meet the specific needs of each application.

The SmartLip ONE TL FFS is the result of this philosophy, combining:

- Nearly 4 decades of experience (38 years) in blown film extrusion

- Made in Germany production with global presence in over 61 countries

- Specialized technical support and complete operator training

- Strong customer relationships through continuous partnership

Benefits for Your Operation

Implementing the SmartLip ONE TL FFS in your production line can result in:

- Significant productivity increase: Throughputs of up to 600 kg/h with up to 45% production increase

- Superior quality improvement: Up to 70% reduction in thickness profile tolerances, ensuring more uniform film

- Easy operation and maintenance: Facilitated cleaning with elevation device and intuitive adjustments via two wheels

- Greater process stability: Advanced insulation minimizing condensation and quality issues

- Simplified installation: Single air inlet reduces complexity and infrastructure costs

Conclusion

The SmartLip ONE TL FFS (2026 model) represents an important milestone in the evolution of air ring technology for FFS film. Combining innovation, performance, and operational ease, this equipment is prepared to raise production standards in the packaging industry.

If your company works with FFS film and seeks to increase productivity, improve quality, and reduce operating costs, the SmartLip ONE TL FFS is the ideal solution.

Contact the Octagon team to discover how we can boost your blown film process and deliver exceptional results for your operation.