Discover the technologies we unveiled at K 2025

- Home

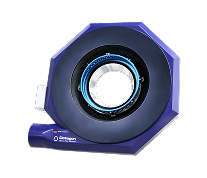

- SolutionsAutomatic Air Ring

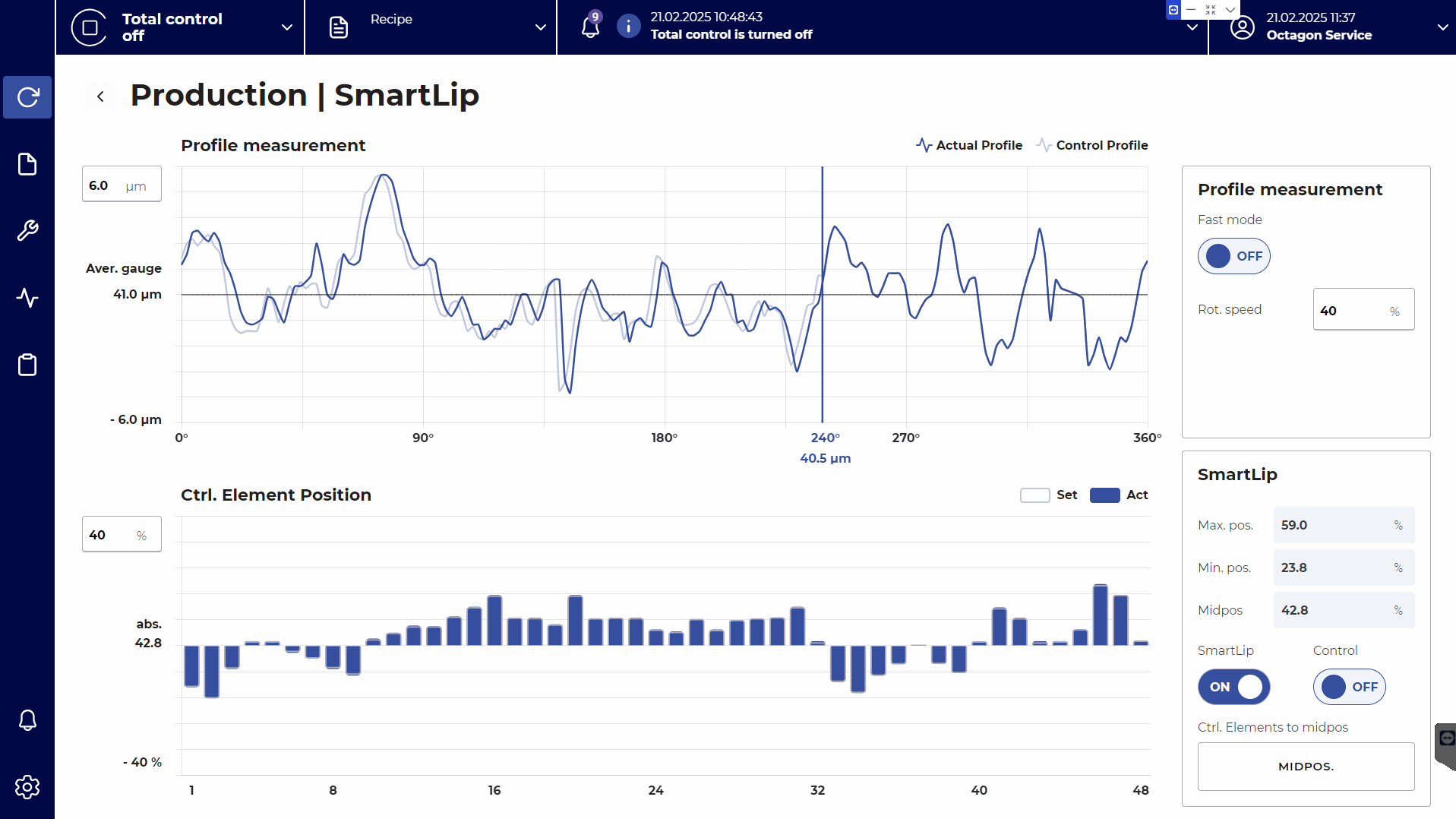

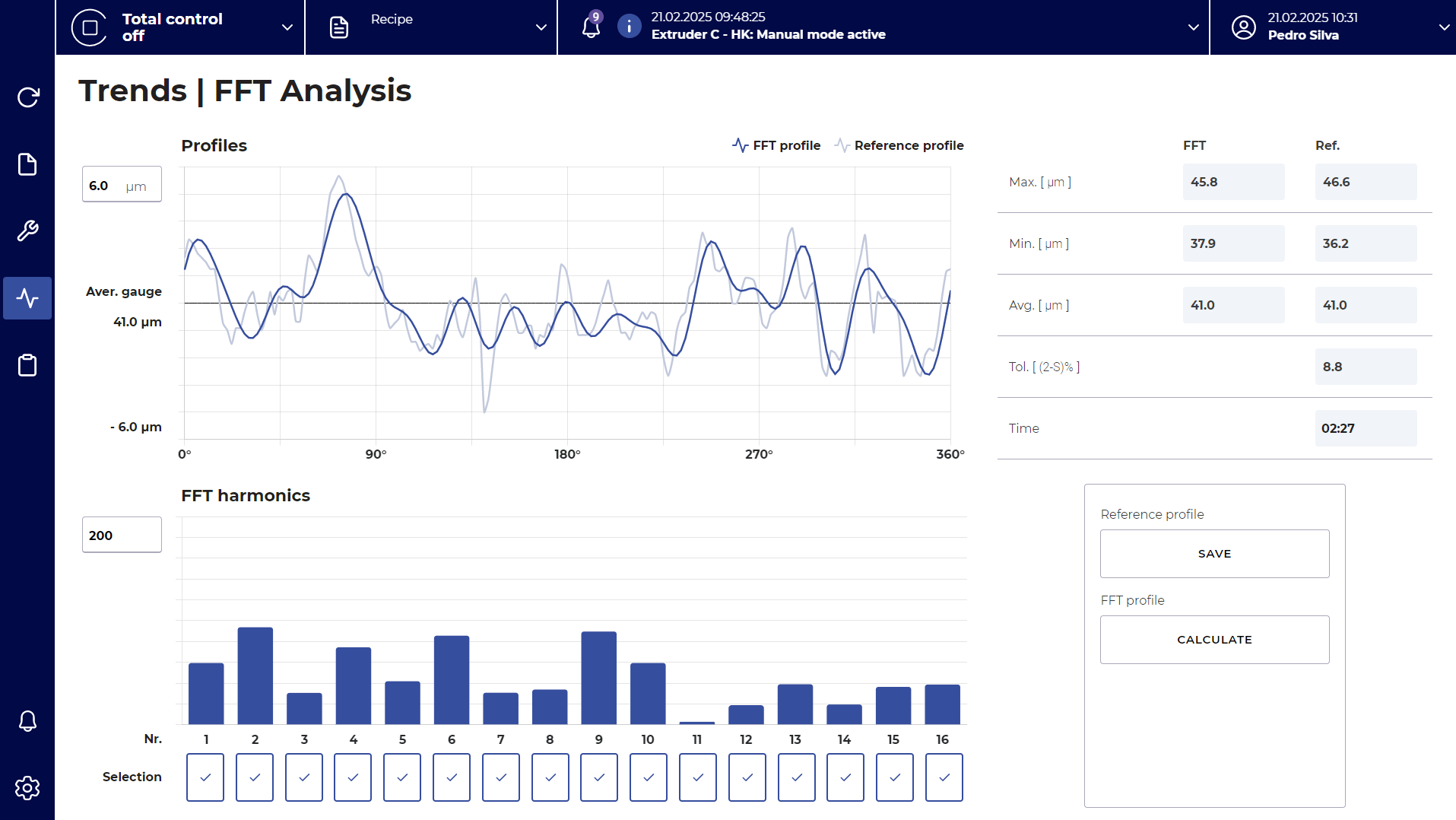

Control film thickness and achieve constant film gauge automatically.

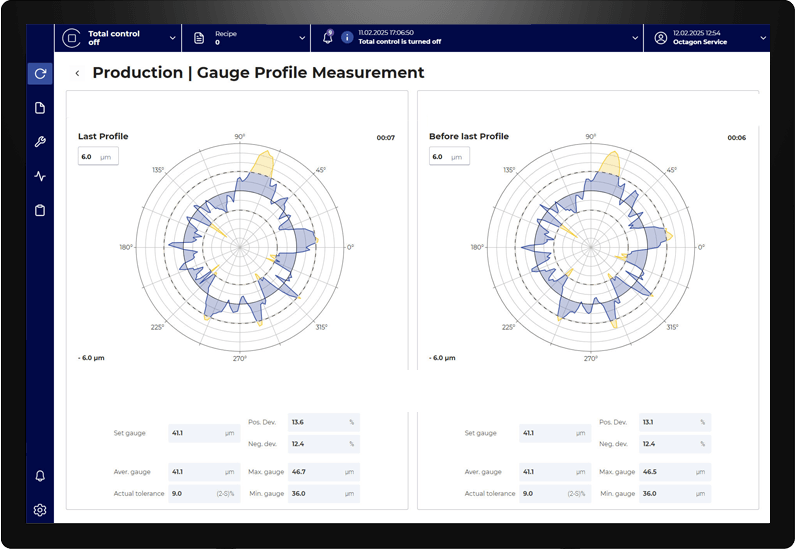

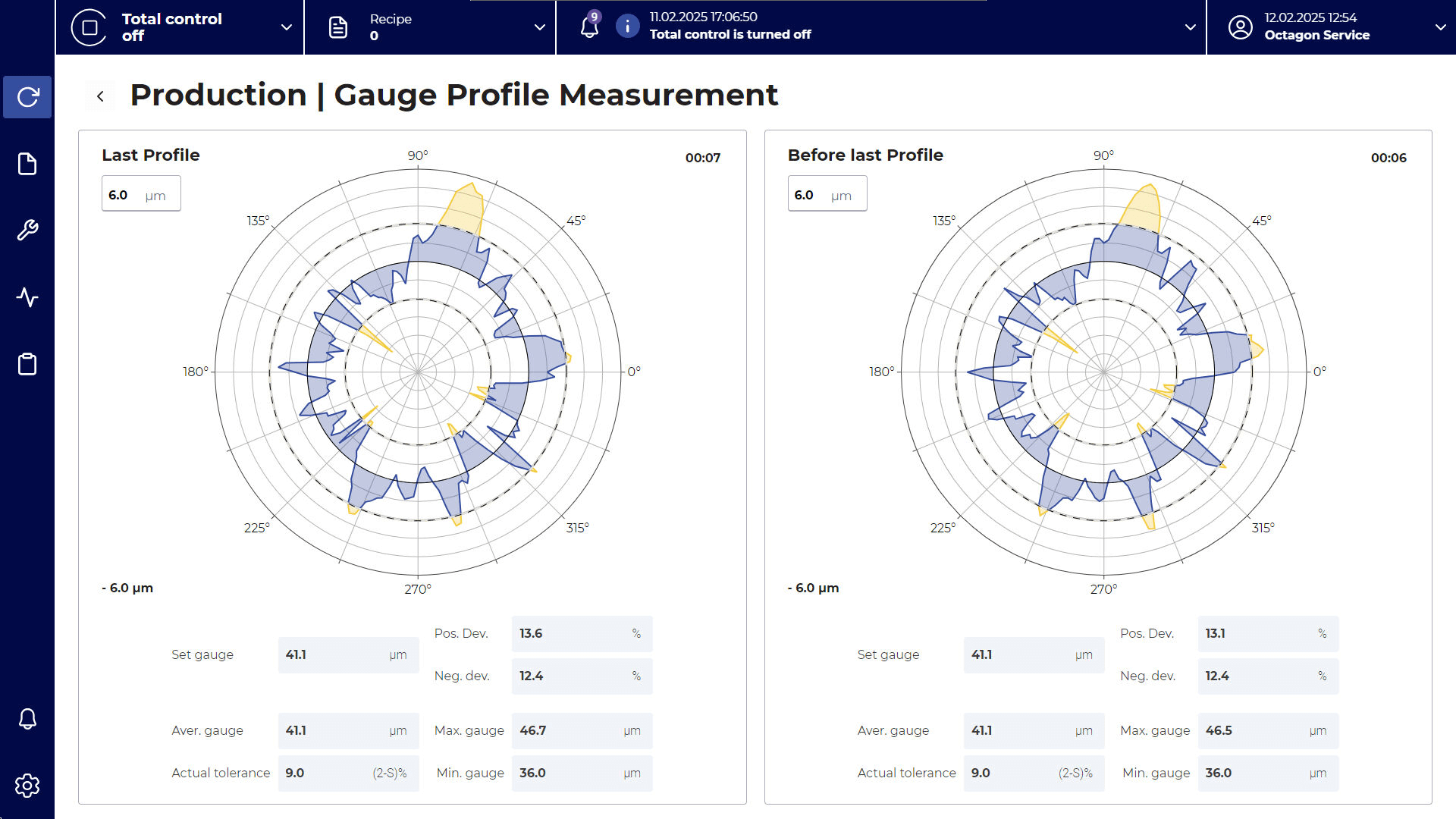

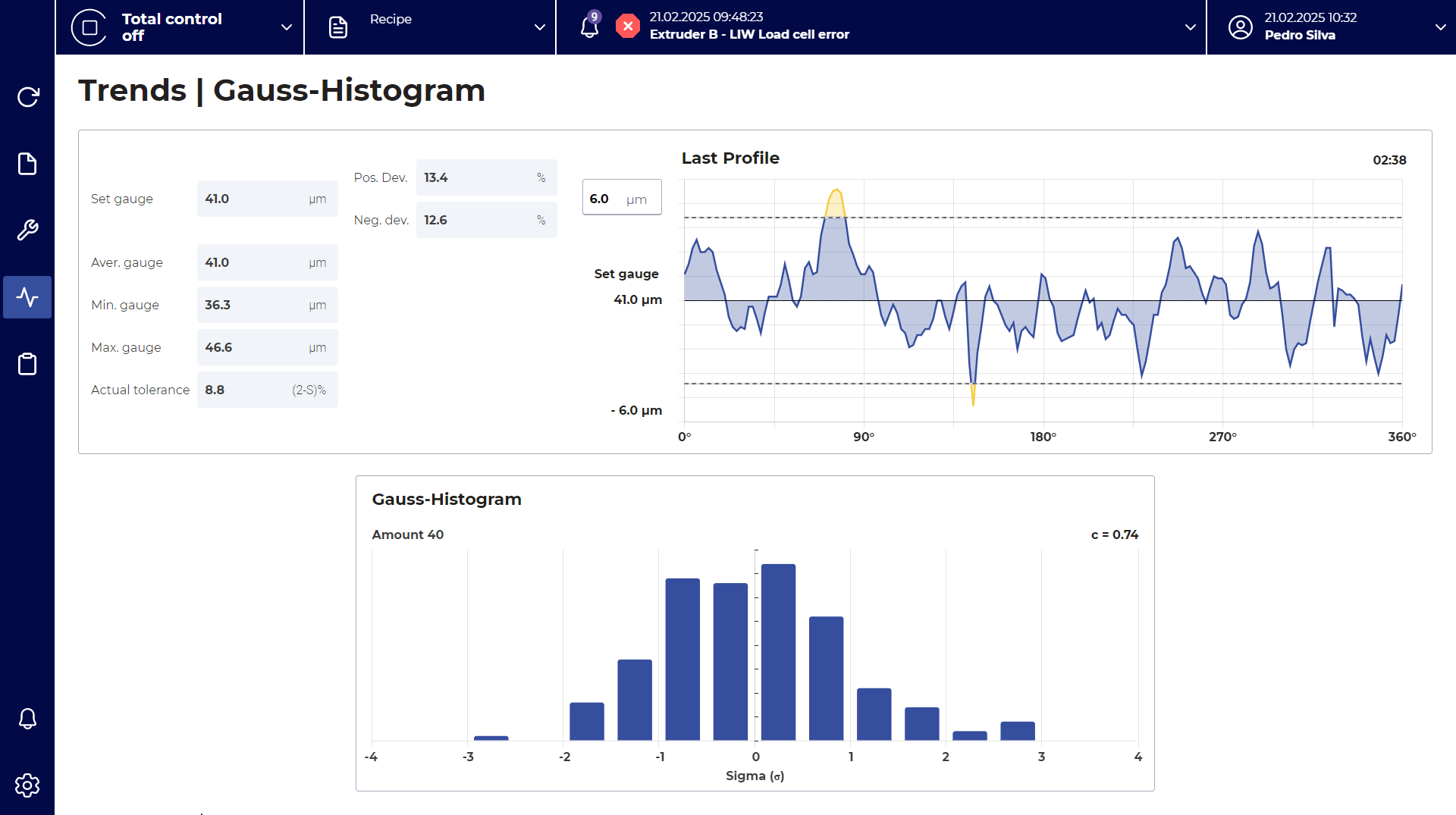

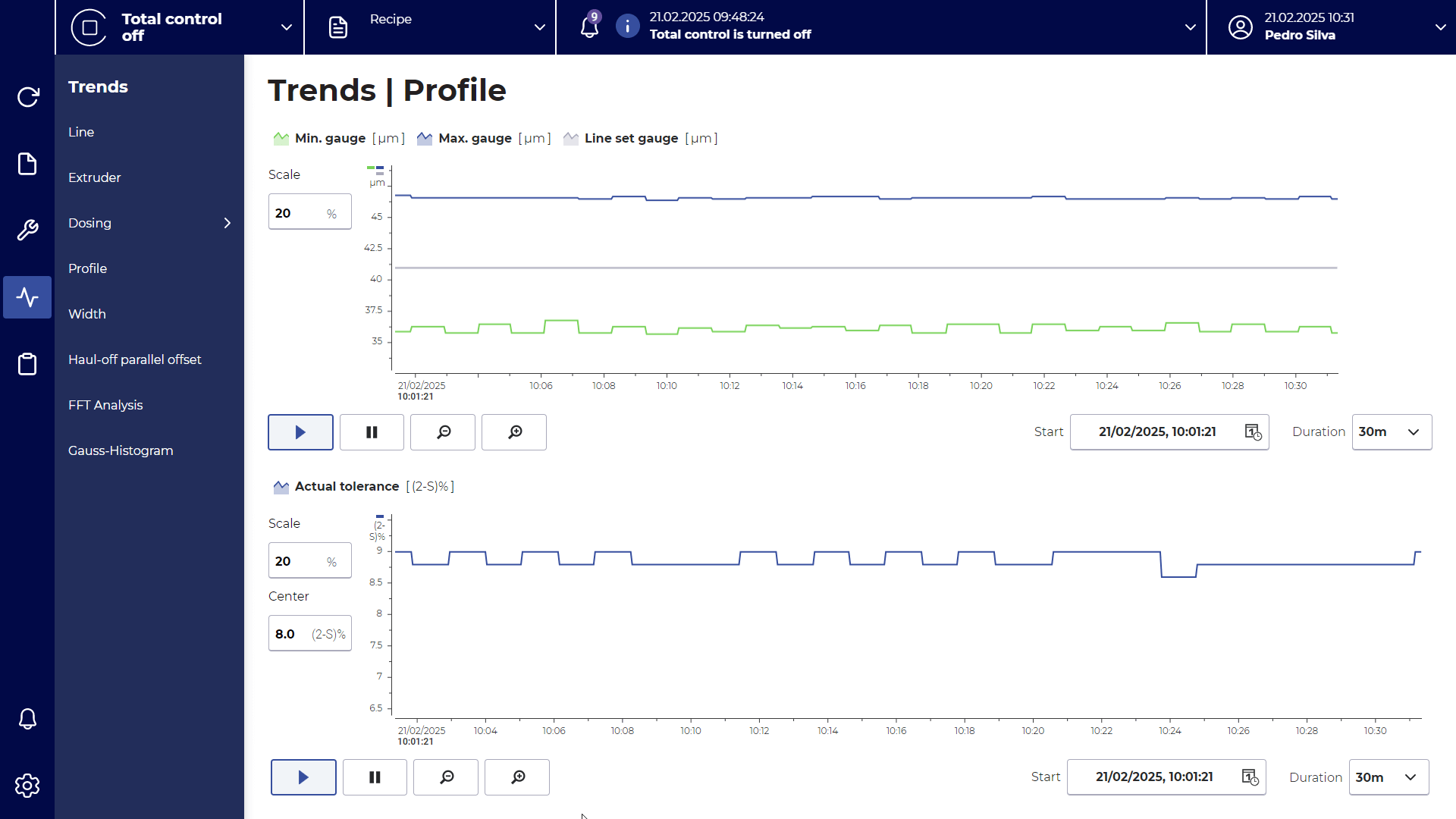

Film Thickness MeasurementInline and real-time gauging data to automate film production adjustments.

Offline Film GaugingMeasure plastic film thickness in lab and guarantee quality expectations

Film Width ControlMeasure and automatically control the width of your plastic film extrusion line.

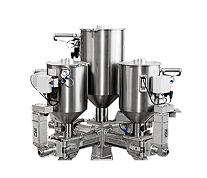

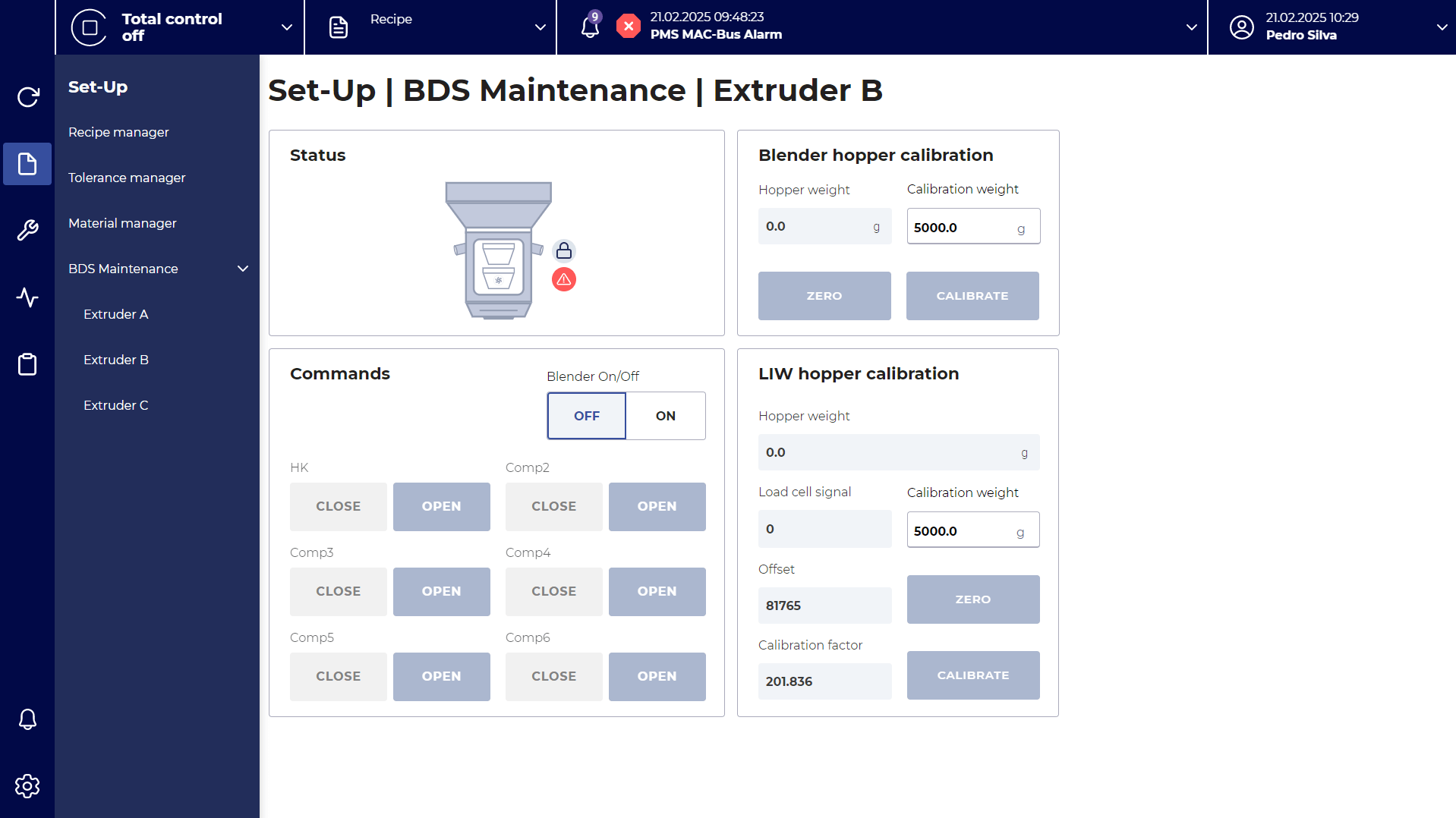

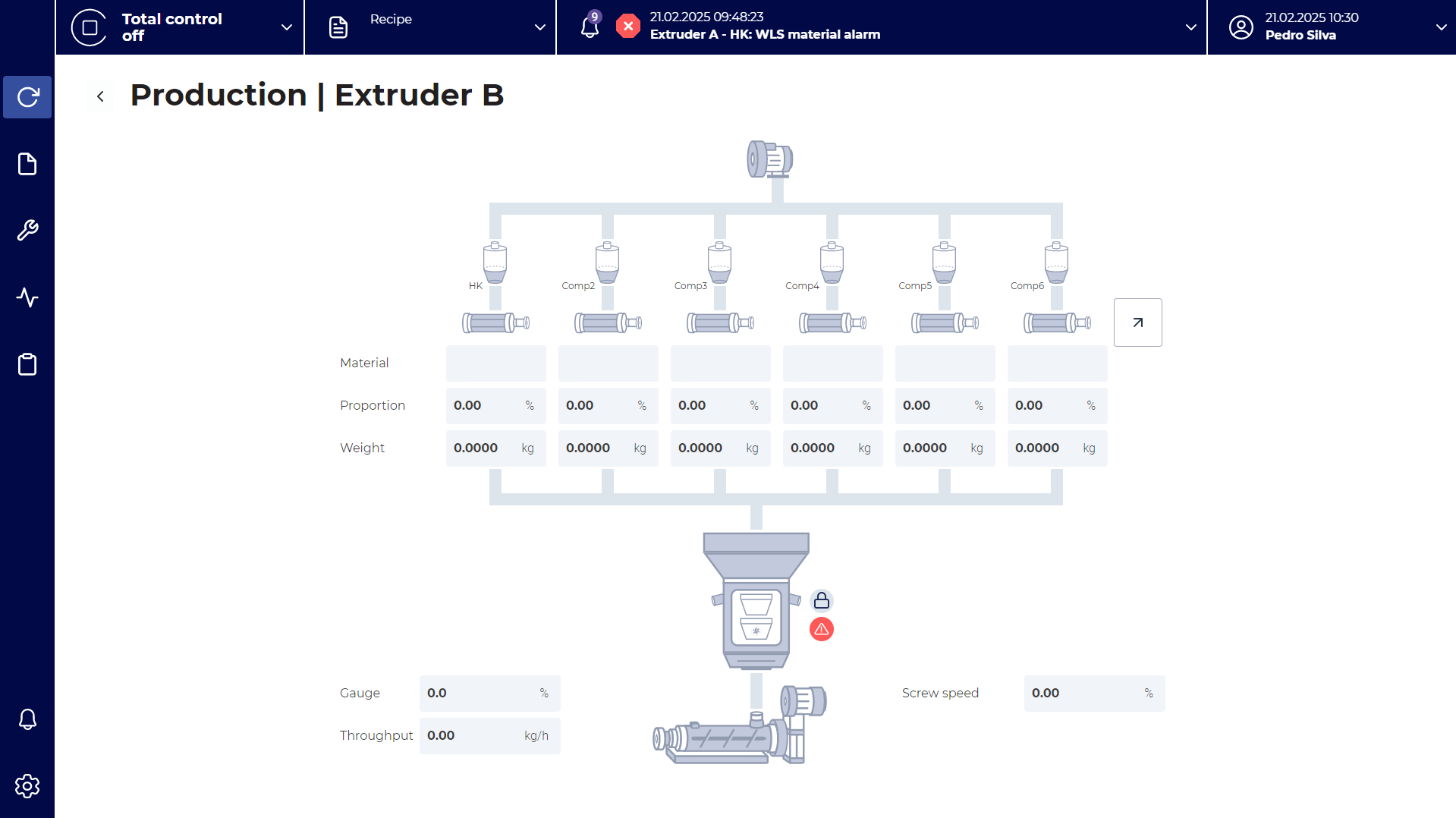

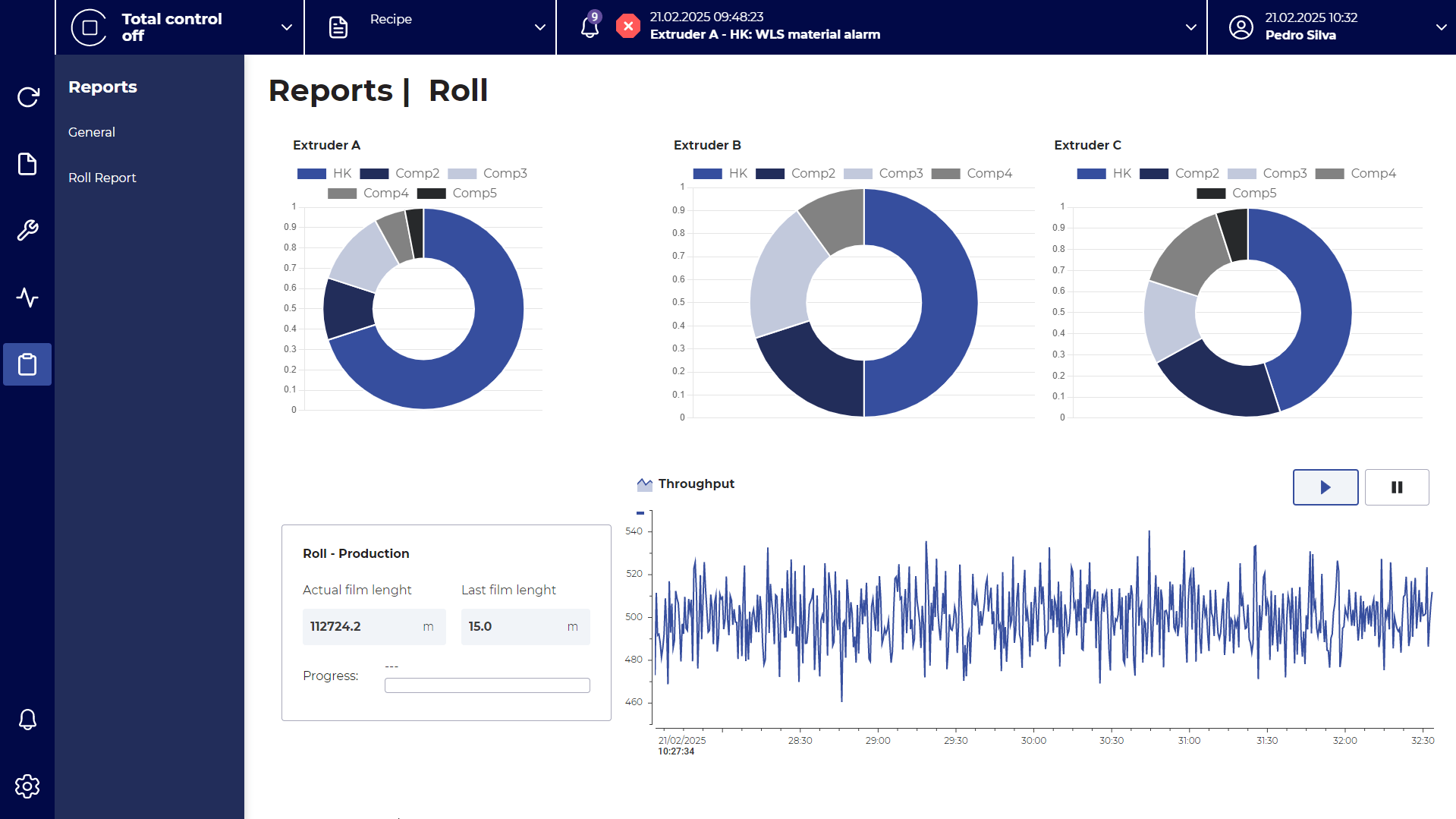

Gravimetric DosingLoss-in-weight gravimetric technology for high-precision dosing and blending.

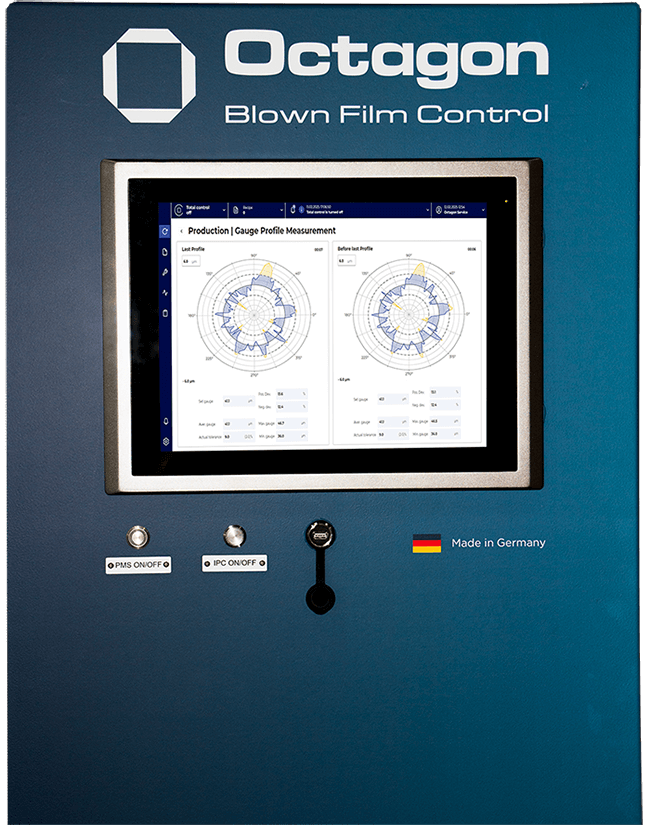

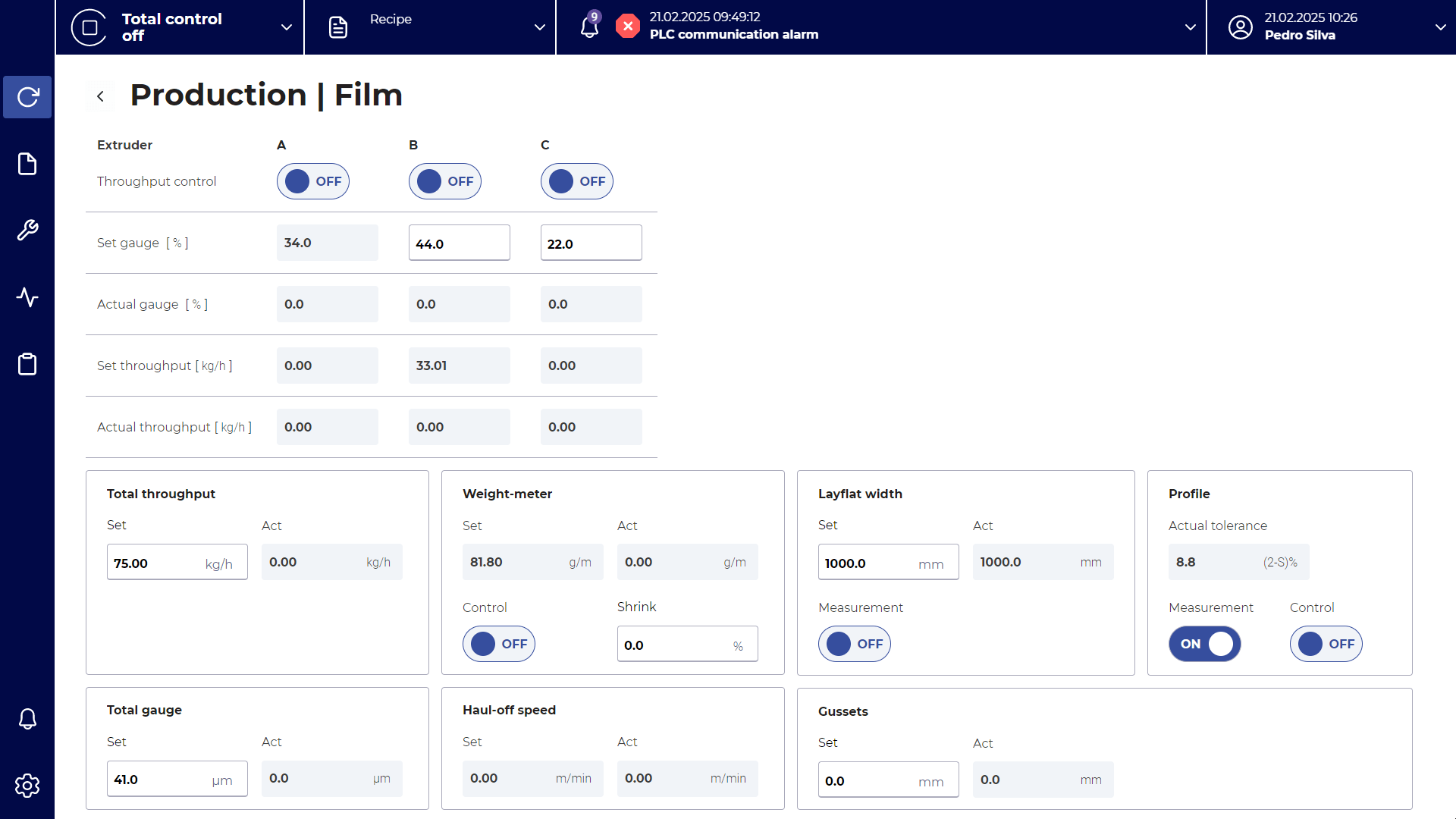

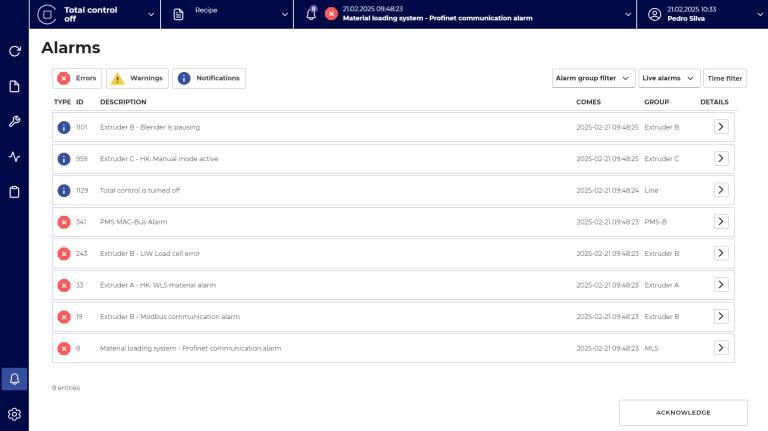

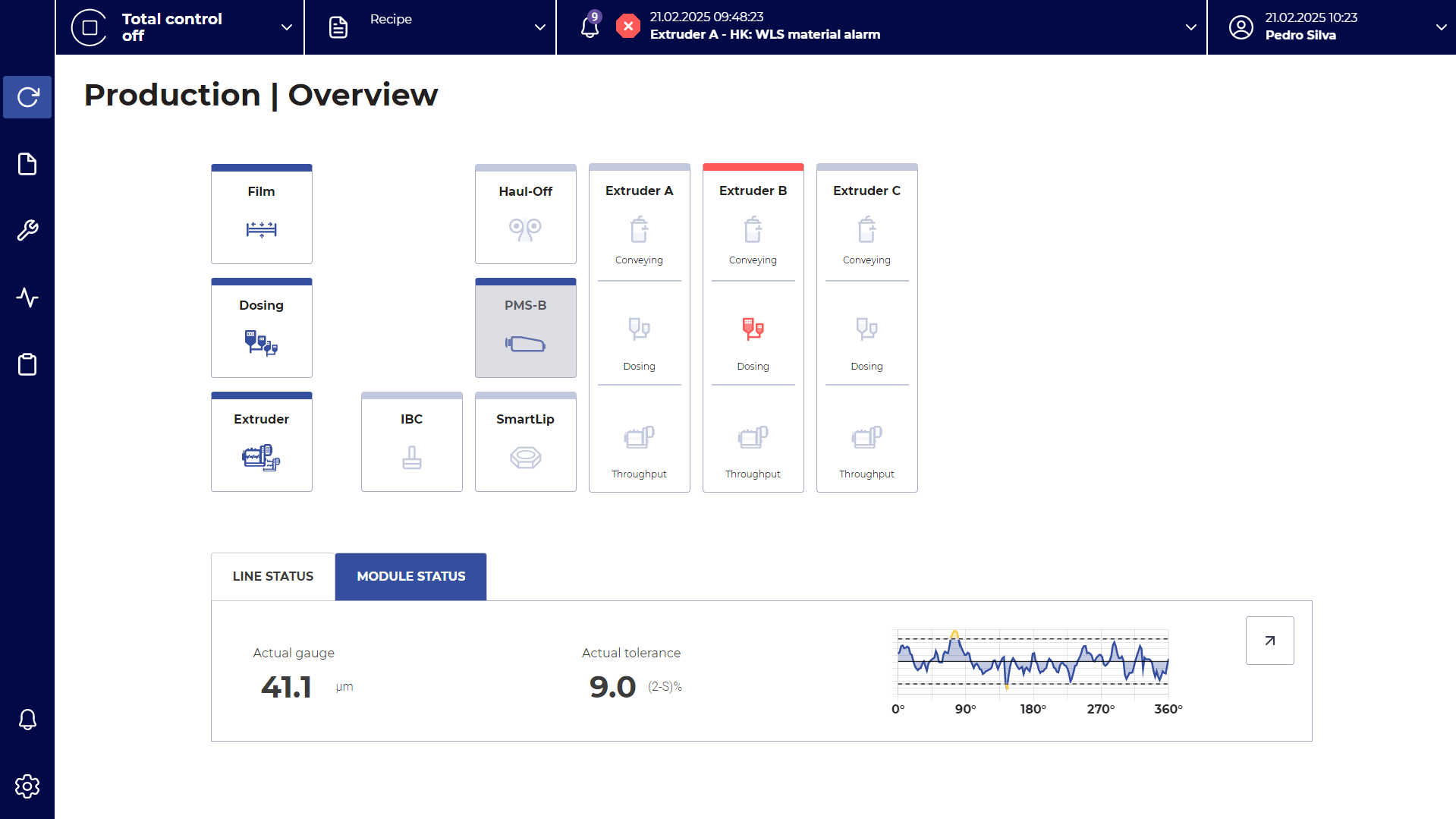

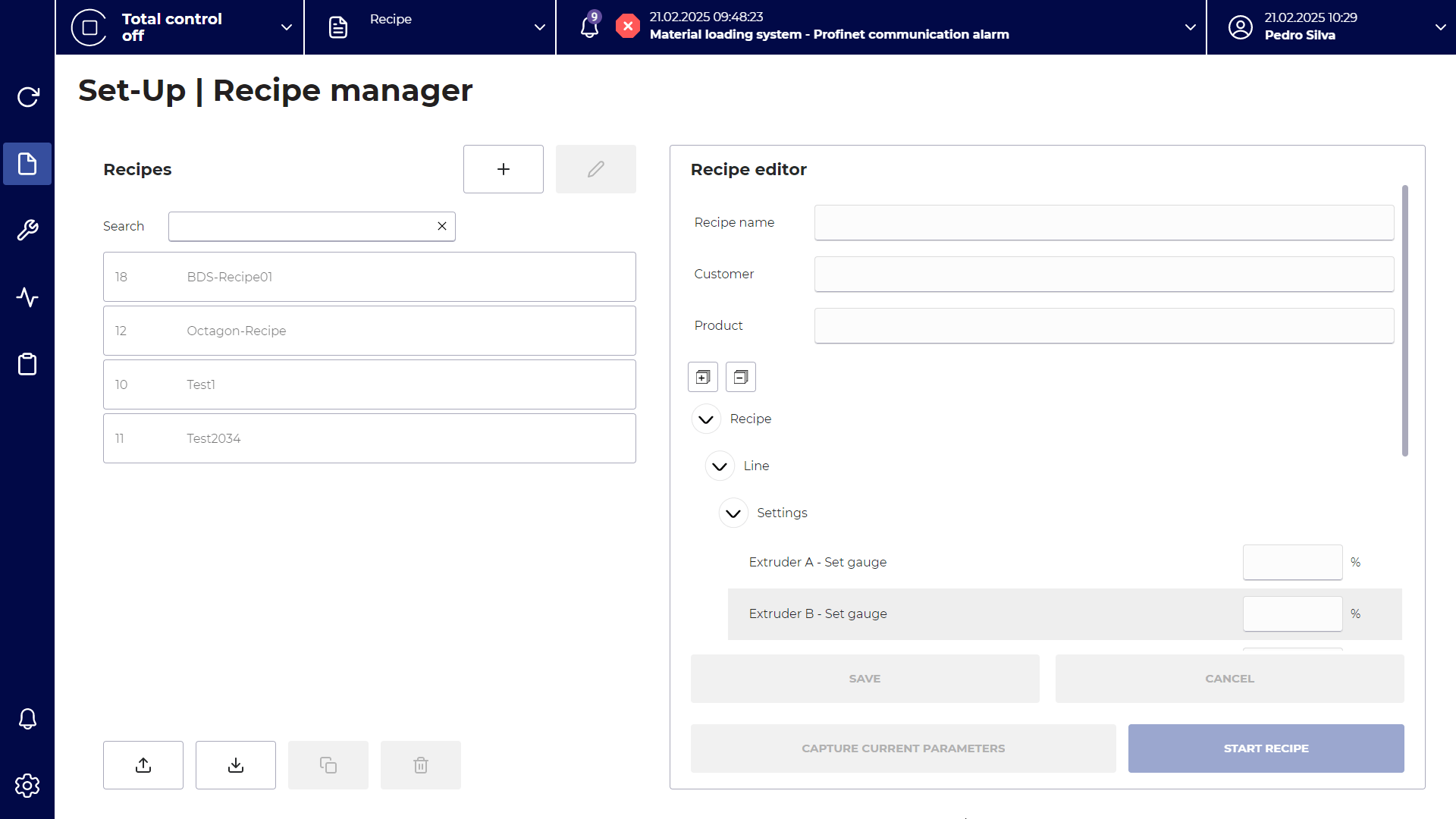

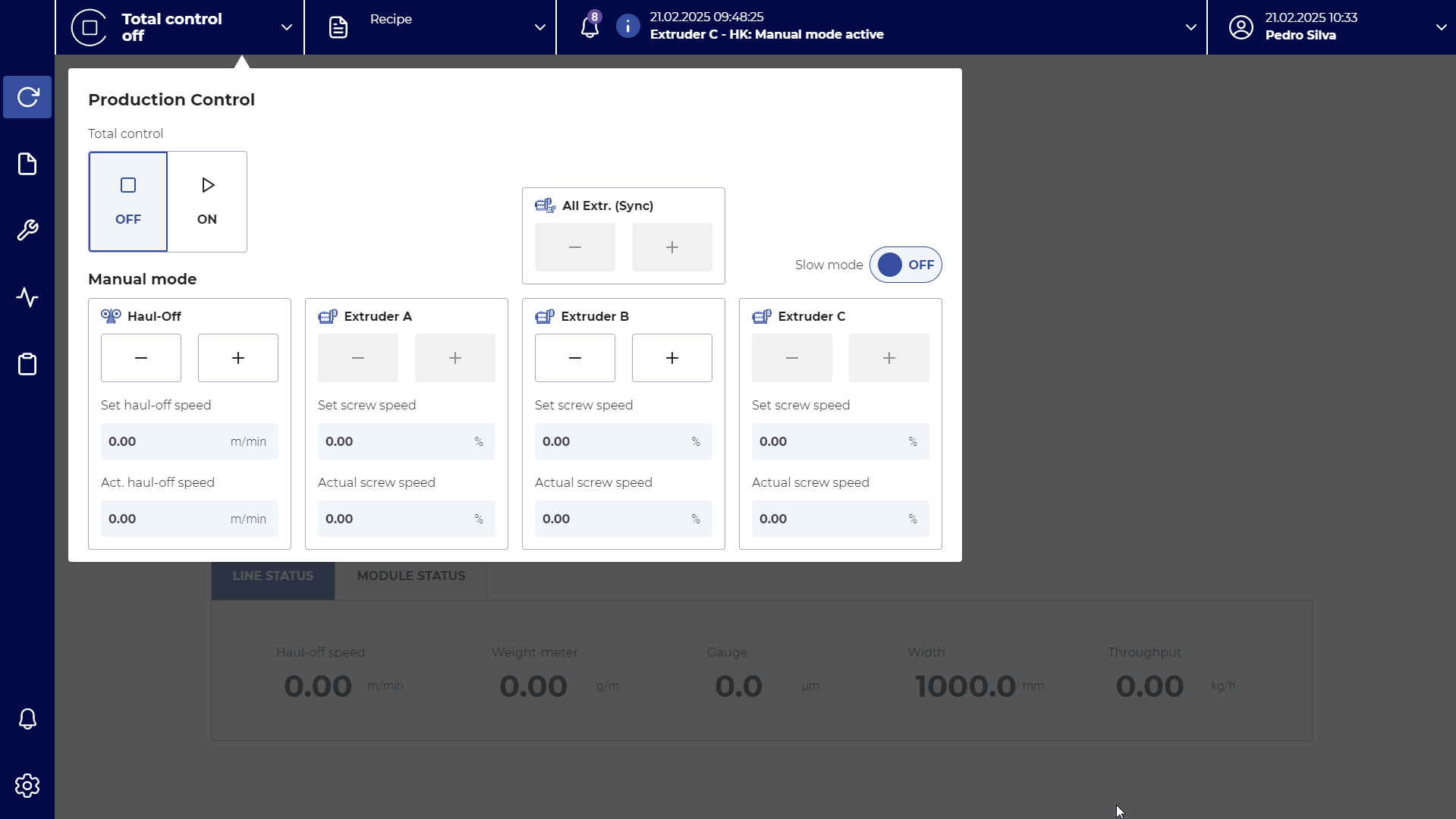

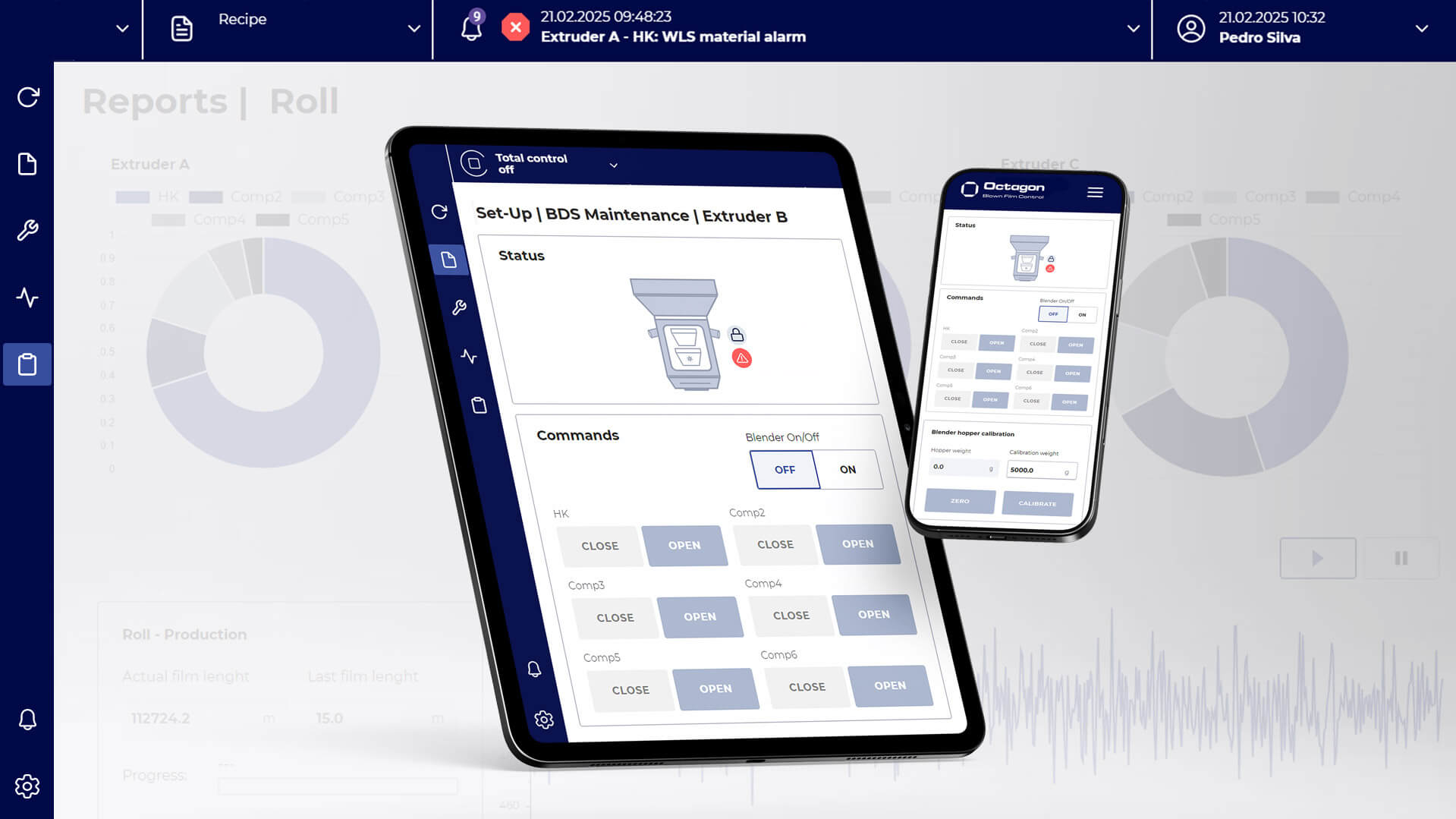

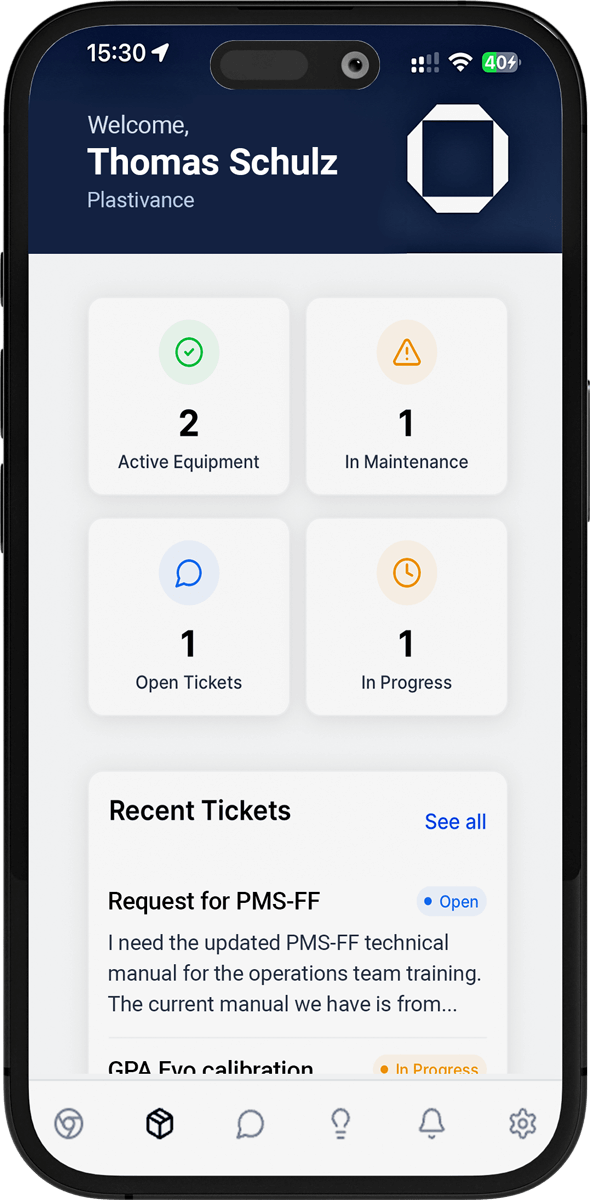

Film Production ManagementSystems and software to automate quality control for plastic film extruders.

Bubble Stabilization ControlBubble control and stabilization for dimensional uniformity and superior film quality.

Raw Material FeedingIntelligent vacuum-based raw material feeding system with full automated operation.

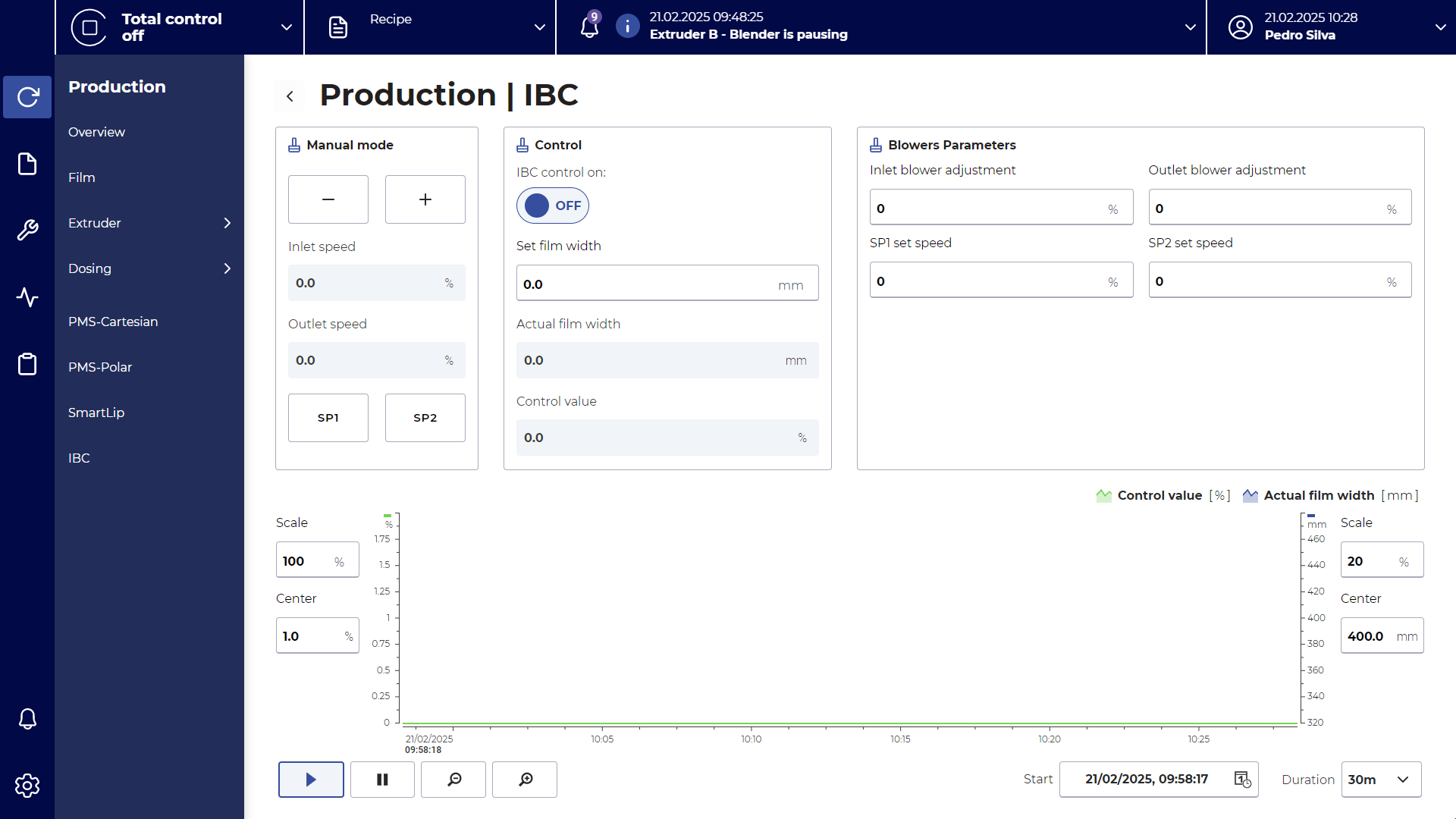

Internal Bubble Cooling (IBC)Internal bubble cooling with high-precision dynamic control technology

Film Extruder UpgradeCustom projects and retrofitting of legacy and outdated extrusion lines.

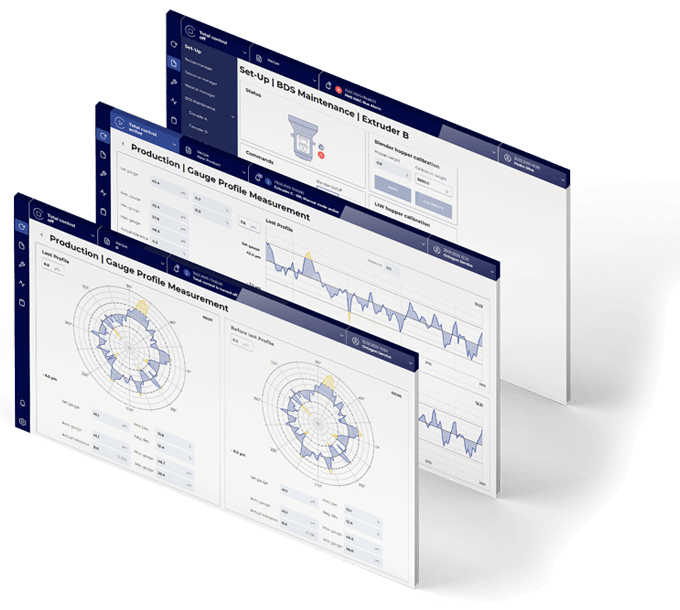

LAUNCH: ScenEx Pro

Discover the new generation of software for plastic film extrusion with integrated Artificial Intelligence. Complete automation, predictive analytics and centralized control that transform your production.

Read More - About Us

- Support

- News