Exclusive event at Flex Pack in Bogotá demonstrates in practice the results of complete integration between Octagon and MegaSteel

Carl Andreas Janzen (Octagon CEO) and Carlos Gonzalez (Flex Pack Owner) during the Open House in Bogotá

During Andina Pack 2025, held from November 4-7 in Bogotá, Colombia, Octagon promoted one of the most significant events of its presence in Latin America: an exclusive Open House at Flex Pack’s facilities that brought together 30 companies from the plastic packaging sector to witness German technology operating in real production.

More than a trade show: an immersive experience

Unlike traditional trade show demonstrations, where equipment operates under controlled conditions, Flex Pack’s Open House offered something rare in the industry: the opportunity to see a complete extrusion line operating 24 hours a day, 7 days a week, in a real commercial production environment.

“The proposal was clear: to show not what our systems can do, but what they do every day in production,” explains the Octagon team. “We wanted visitors to see real challenges, process variations, and how our technology responds in real time.”

Flex Pack: a factory designed for the future

Flex Pack, under the leadership of Carlos Gonzalez, recently inaugurated its new facilities in Bogotá, an exclusive architectural project dedicated to the flexible packaging industry. With high ceilings, natural lighting, spacious production areas and modern infrastructure, the factory represents the state of the art in facilities for plastic film extrusion.

MegaSteel 3-layer co-extruder equipped with Octagon technology in full production

The line in operation: technical specifications

During the Open House, visitors were able to observe a MegaSteel 3-layer co-extruder operating continuously, equipped with the latest in quality control for blown film extrusion.

Extruder configuration

Base structure:

- MegaSteel 3-layer co-extruder

- Extruders: 55mm / 65mm / 55mm

- 300mm die

- Maximum width: 1.80m

Cooling system and thickness control:

- SmartLip DL 350 – Dual Lip automatic air ring

- Full thickness profile control in 360°

- Real-time automatic adjustments

- Instant response to process variations

Gravimetric dosing:

- 3 SmartBDS dosing systems with 6 components each

- Accuracy up to 0.01% of batch volume

- Individual control of each component

- Complete consumption traceability

Feeding system:

- Integrated vacuum system

- Feeding on the first floor of the extruder

- Efficient pneumatic transport

- Contamination minimization

Software and connectivity:

- ScenexPro – Industry 4.0 software

- Complete web interface

- Real-time reports

- Total integration of all systems

The impressive numbers

During the Open House days, the line operated producing 30-micron lamination film, an application that requires extreme precision and stability. The demonstrated results were:

Production performance

Productivity:

- 300 kg/h continuous production

- 24/7 operation without interruptions

- Zero stops due to quality issues

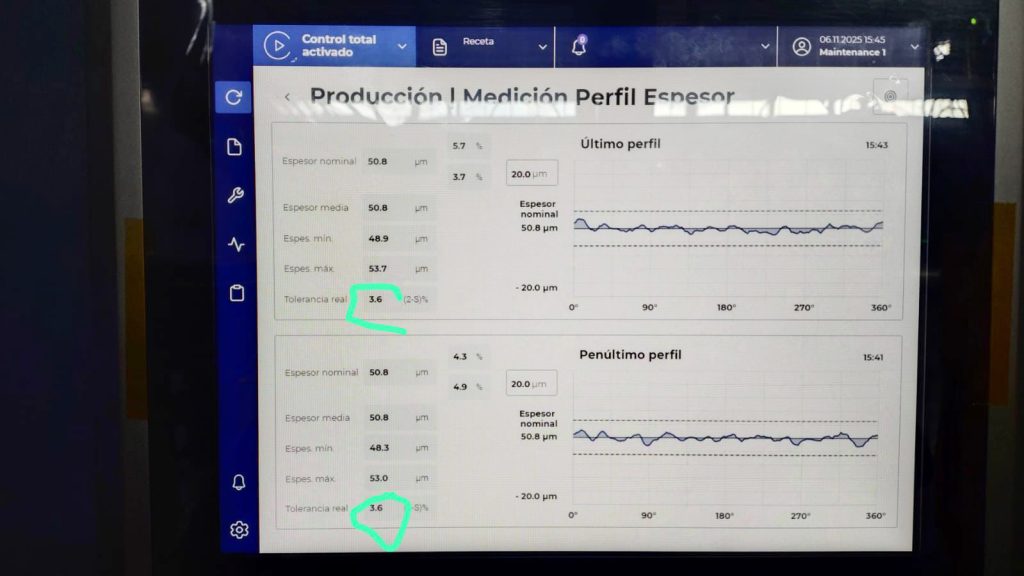

Quality:

- 3.6% total thickness variation

- Nominal thickness: 50.8 µm

- Average thickness: 50.8 µm

- Minimum thickness: 48.9 µm

- Maximum thickness: 53.7 µm

- Actual tolerance: 3.6% (±2σ)

“Seeing 3.6% variation in real production, with 30-micron film, is something that impresses even the most skeptical. It’s not a demonstration, it’s commercial production happening right in front of us.”

– Open House visitor

ScenexPro interface showing real-time thickness profile with 3.6% variation

SmartLip DL 350: the heart of the system

One of the great technical highlights of the demonstration was the SmartLip DL 350 automatic air ring, which not only controls bubble cooling but fully integrates with all line systems.

Technical features

Exclusive design:

- Single air inlet (eliminates turbulence)

- Dual Lip technology for fine control

- Robust stainless steel construction

- Simplified maintenance

Automatic control:

- 360° real-time thickness measurement

- Proprietary profile correction algorithm

- Automatic adjustments without operator intervention

- Millisecond response to variations

Integration:

- Direct communication with extruders

- Synchronization with gravimetric dosing systems

- Data available in ScenexPro

- Remote control via web interface

“The SmartLip is not just an air ring, it’s the brain that coordinates the entire extruder,” explains Octagon’s technical team. “It receives data from the thickness sensor, processes the correction algorithm, adjusts air flow in each zone, and still feeds information to the management system. All of this happening hundreds of times per second.”

SmartLip DL 350 controlling the bubble, single air inlet eliminates turbulence

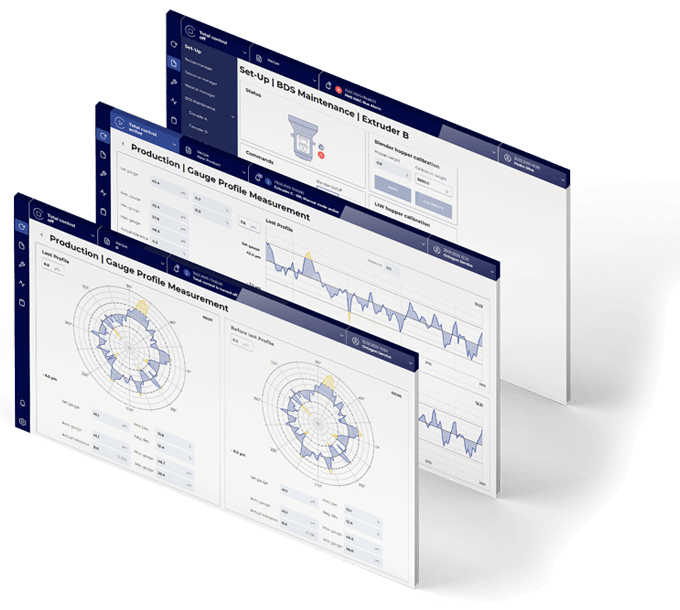

ScenexPro: Industry 4.0 in practice

Another point of great interest to visitors was the ScenexPro software, which centralizes control and monitoring of the entire production line.

Demonstrated functionalities

Real-time monitoring:

- Visualization of all process parameters

- Trend graphs and historical analysis

- Automatic deviation alerts

- Status of all equipment

Integrated control:

- Setpoint adjustment of all systems

- Automatic synchronization between equipment

- Stored production recipes

- Quick product changeover

Industry 4.0 reports:

- Automatic documentation of each reel

- Complete raw material traceability

- Performance analysis (OEE)

- Export to ERP systems

Remote access:

- Web interface accessible from any device

- Remote technical support

- Automatic data backup

- Security and encryption

“Being able to see data in real time, understand how the system makes decisions, and still have access to all this remotely, that’s Industry 4.0.”

– Production manager present at the event

https://youtu.be/hTxlLn8PGiM

ScenexPro dashboard showing integrated control of the entire line

30 companies, a unique experience

During the four days of Andina Pack, 30 companies from the plastic packaging sector visited Flex Pack’s facilities. The profile of visitors included:

- Production managers and directors

- Process engineers

- Quality managers

- Equipment investment decision makers

- Specialized extrusion technicians

“The diversity of visitors greatly enriched the discussions,” comments the Octagon team. “We had everyone from people with 30 years of experience in extrusion to young engineers just starting out. Each group brought different questions, different challenges, and that made the event very rich.”

Participant feedback

About real production:

“Seeing the machine operating 24/7, with all real production variables, was fundamental to our investment decision.”

About technology:

“The 3.6% variation is not propaganda, we saw it happen. And in 30-micron film, that’s impressive.”

About integration:

“The way all systems communicate with each other through ScenexPro shows that it’s possible to have real Industry 4.0, not just on paper.”

About the Open House:

“Better than any trade show. Here we saw real production, asked detailed technical questions, and left with certainty about what we were buying.”

Strategic partnership: Octagon + MegaSteel + Flex Pack

The success of the Open House would not have been possible without the synergy between three companies committed to excellence in the packaging industry:

Octagon (Germany)

- 38 years of experience in quality control

- Presence in 61 countries

- Cutting-edge automation technology

- Global technical support

MegaSteel (Colombia)

- High-performance extruder manufacturer

- Deep knowledge of Latin American market

- Agile and efficient local support

- Technical partnership with Octagon

Flex Pack (Colombia)

- Leadership in flexible packaging

- Modern and innovative facilities

- Commitment to quality and sustainability

- Trust in Octagon technology

“This partnership represents the best of three worlds. Cutting-edge German technology, quality Colombian manufacturing, and the practical results in our daily production. It’s an unbeatable combination.”

– Carlos Gonzalez, Flex Pack

Next steps and opportunities

The success of the Open House during Andina Pack 2025 reinforces Octagon’s commitment to Latin America and paves the way for new events and partnerships in the region.

For interested companies

If you were unable to participate in the Open House but are interested in learning about Octagon technology in real operation, contact us:

Contacts:

- 📧 Email: contact@octagon-company.com

- 📱 WhatsApp: +57 311 223 3639 (Rafael)

Upcoming events

Octagon is planning new Open Houses in different Latin American countries. To be informed about upcoming events:

- Subscribe to our newsletter

- Follow our social media

- Contact our sales team directly

Conclusion: technology that delivers results

The Open House at Flex Pack during Andina Pack 2025 unequivocally demonstrated that the complete integration between quality control systems, gravimetric dosing and management software is not just theory, it’s reality operating 24/7 and generating measurable results.

The numbers don’t lie:

- 300 kg/h constant production

- 3.6% thickness variation in 30-micron film

- Zero stops due to quality issues

- 30 companies satisfied with the experience

For Octagon, events like this reaffirm its mission: to bring German precision and cutting-edge technology to the plastic film extrusion industry, not through promises, but through proven results in real production environments.

Special thanks

To Flex Pack and Carlos Gonzalez, for opening the doors of their facilities and sharing their experience with the community.

To MegaSteel, for the long-term partnership and commitment to excellence in extruder manufacturing.

And to the 30 companies that visited the Open House: thank you for your trust and interest in raising the level of the Latin American packaging industry.